TM 10-4610-246-13

3.6

MAINTENANCE OF SUCTION VALVE AND TUBING - (Cont)

b.

Disassembly.

(1)

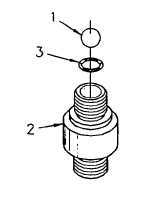

Remove ball poppet (1, Figure 34)

from valve body (2).

(2)

Remove preformed packing (3, Figure

3-4).

c.

Service.

(1)

Discard preformed packing.

(2)

Clean all components of suction valve

and tubing with soap and water.

(3)

Inspect all components for damage.

Replace entire suction valve if any

components are damaged.

d.

Repair.

Repair is accomplished by replacement of

defective parts.

e.

Assembly.

(1) Install preformed packing (3, Figure 34)

into valve body (2).

(2) Insert ball poppet (1) into valve body

(2).

Hand tighten connections. Overtightening could result in damage.

f.

Installation.

(1)

Install preformed packing (5, Figure 3-3) on valve body (3) and screw valve body into pumper assembly

(4). Hand tighten.

(2)

Install suction tubing (1) onto valve body (3).

(3)

Screw tube nut (2) onto valve body (3) and hand tighten.

(4)

Install foot valve (refer to para. 3.5).

3-10