MANUAL RELEASE (See Figure 5)

To manually release the brake, rotate release knob (21)

clockwise until it strikes stop pin (22). The brake will

remain in the release position until manually reset, or

automatically reset when electric power is restored.

MAINTENANCE AND SERVICE

FRICTION DISC REPLACEMENT (See Figure 5)

When total wear on rotating friction disc reaches

1/16',;replace as follows:

Remove cover. With release knob (21) in released

position, remove three mounting screws (27) and-

remove operator assembly (6) as a unit Spring (5). is a

loose part. Avoid loss. Remove stationary discs (3),

install new rotating discs (4) and reassemble all parts in

reverse order. After starting three screws (27), turn two

wear adjustment screws (26) counterclockwise to allow.

the three posts on end plate assembly (7) to seat

against the bracket (2). Tighten screws (27). Readjust

magnet gap (see WEAR ADJUSTMENT). Replace

cover.

MAGNET ASSEMBLY REPLACEMENT

Remove cover. Unscrew two flat head screws (13),

remove shoulder nuts (12) and rubber washers (11).

Remove and replace magnet assembly (9) and

reassemble' parts in reverse order. Magnet and

armature faces must be clean and parallel to insure

quiet operation (see WEAR ADJUSTMENT -' and

TROUBLE SHOOTING). If manual release does not

operate properly, see TROUBLE SHOOTING.

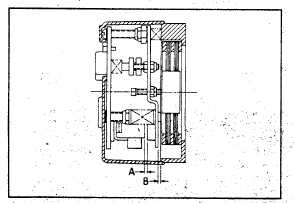

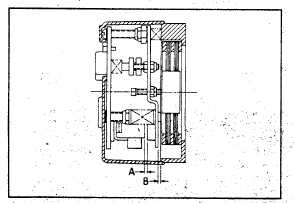

Figure 3. Brake Cap Adjustment

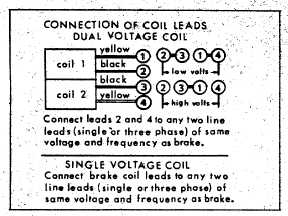

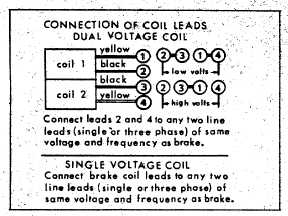

Figure 4. Wiring Diagram

WEAR ADJUSTMENT (See Figure 3)

When armature plate (25) touches bracket (2), closing

gap "B,' adjustment for friction disc wear is required.

Turn two screws (26) clockwise until magnet gap 'A"

reads .040" to .045" at narrowest gap, for 1 and 2 disc

'models, and reads .050" to .055" at narrowest gap, for 3

disc models. Any delay in adjusting gap will result in

eventual loss of torque.

TORQUE ADJUSTMENT

The 60 Series Brake is factory set for rated static torque.

To increase stopping time and lower torque, turn two

.locknuts above torque springs (16) counterclockwise,

increasing spring length. Each full turn decreases

torque by approximately 10%. Do not adjust brakes for

higher torque, as this will cause premature coil burnout.

TROUBLE SHOOTING

BRAKE DOES NOT RELEASE

Check for failure of power supply to brake.

Check brake visually for broken or damaged parts.

Check for broken leadwire or bad electrical connection.

Check for correct voltage. Voltage must correspond to

that listed on brake nameplate. If voltage is

more than 10% below figure stamped on

nameplate, magnet will not pull in, causing coil

to burn out within minutes. If voltage is more

than 10% above, coil will overheat and burn out.

Check for burned out coil (coil may be charred or

burned).

BREAK DOES NOT STOP

Check that manual release is in normal reset position.

Check brake visually for broken or damaged parts.

Check disc wear (See WEAR ADJUSTMENT).

Check for broken friction disc.

Make certain hub has not shifted position on shaft and

that all rotating discs are fully engaged on hub.

BRAKE CHATTERS OR HUMS

Clean magnet faces if dirty. Insert a clean sheet of

paper between magnet faces and energize brake. Move

paper around between faces to dislodge dirt. Finally,

remove paper.

Check that magnet faces are parallel in closed position.

1.

If not parallel along length of magnet, check

bushings (14) under torque springs for binding

or excessive wear.

2.

If not parallel across width of magnet, adjust

pivot nut (8) on post to obtain minimum magnet

hum. After adjusting pivot nut, lock in place

with nut (item 7, part "C"). Check magnet gap

"A" and adjust if necessary (See WEAR

ADJUSTMENT ). Operate manual release (21)

and adjust if necessary.

Check if shading coil (10) is cracked, broken or out of :

position. Replace magnet assembly if cracked

or broken.

Check for low voltage. Magnet will not pull in and coil

will burn out if voltage is more than 10% below

figure stamped on nameplate.

MANUAL RELEASE DOES NOT WORK Check for

broken or damaged parts.

Check return spring (24). Brake will not reset

automatically if this spring is broken.

Check magnet gap "A" with knob in released position.

Gap must be .030" at narrowest point. If gap is too

wide, motor shaft will not turn freely. If gap is too small,

knob will not return automatically when power is applied.

Adjustment for correct magnet gap is made by turning

nuts (18 and 19). Make sure nuts are tight against

armature

plate

(25)

after

adjusting

release.