#3500H1A, or ARK-LES #3500H4A) to the wires by

squeezing or crimping terminal barrel until it firmly grips

the conductor. Assemble conductor and terminal

insulator (Shrink Tubing Alpha Wire and Cable Co. #

Fit-221-1/4", ¼” i.d. x 1" Ig.), using heat source to

appropriate conductors.

6.

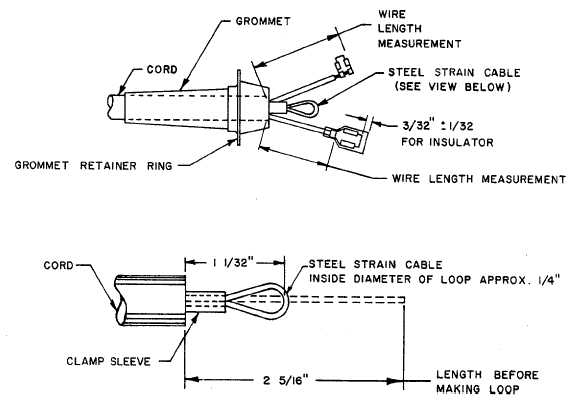

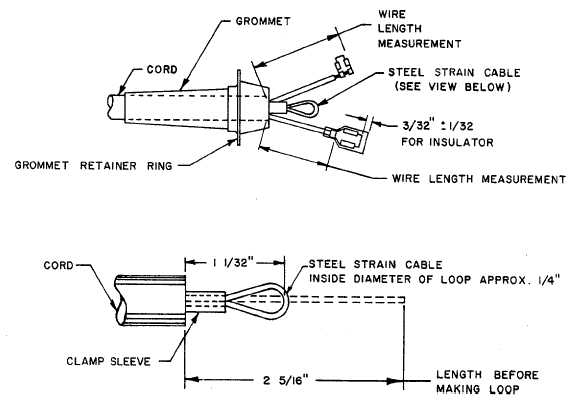

Shorten steel strain cable (Green wire) and strip

insulation for 2/16 ".

7.

Slide clamp sleeve (Nicopress sleeve type 18-1-

C) onto strain cable. Form a tight loop in cable

at a length of 11/2'3 from end of outer

insulation jacket, inserting the loose end into

sleeve.

8.

Squeeze or crimp sleeve with a vise or large

pliers to secure loop.

9.

Remove (from the cut off piece of cord) the

rubber sleeve covering the loop clamp and slip

it over the clamp sleeve which you just

prepared. Or, cover sleeve with vinyl electrical

tape.

10.

Insert control cord into control station case.

Attach steel strain cable.

11.

Refer to wiring diagram inside back fram cover

of hoist (or packed with hoist) and care fully

reconnect wires.

12.

Reposition the neoprene grommet so that it fits

in top of control station case and assemble

grommet retainer ring. Reassemble cover and

gasket.

13.

Operate hoist carefully in both directions to

check correctness of electrical connections.

FIGURE 5.

SHORTENING CONTROL CORD

6