SECTION E - REPLACEMENT PARTS LIST

Ordering Instructions

The following information must accompany all

correspondence or replacement parts orders:

1.

Hoist model

2.

Serial number of hoist

3.

Voltage, phase, hertz

This information is marked on the hoist

identification plate.

When ordering trolley parts, also specify the

trolley capacity.

For parts orders specify:

1.

Quantity desired

2.

Key number of part

3.

Part name

NOTE: When ordering replacement parts, it is

suggested that the individual also consider the need (if

he has not done so already) for such items as gaskets,

fasteners, etc. These items may be damaged or lost

during disassembly or may be just unfit for future

service because of deterioration from age or service

conditions.

The parts shown on pages 29-38 are for current

hoists and trolleys. Additional parts which were used on

older units are listed on pages 40-54.

Assembly Instructions

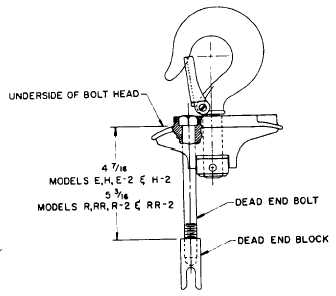

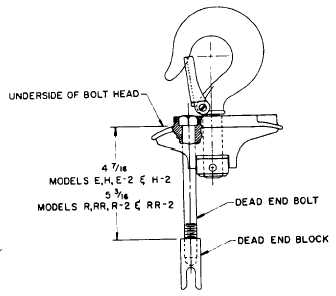

HOOK OR LUG SUSPENSION - Models E, H, R,

RR, E-2, H-2, R-2 and RR-2.

Assemble the dead end bolt and block through

the suspension adapter as shown in Figure 16.

CENTRIFUGAL MECHANISM

Centrifugal Mechanisms (S-430) are furnished

in kit form which contains the centrifugal mechanism,

spacers and an Instruction Sheet. The Instruction Sheet

provides complete details on the installation of the

replacement mechanism.

To install the replacement mechanism, a press-

on tool (shown in Figure 17) will be required. The press-

on tool is not included in the kit, however, it may be

ordered from the Factory order Centrifugal Mechanism

Press-On Tool Key No. S-438.

When installing the replacement mechanism,

the spacer is placed between the rotor shaft shoulder

and the centrifugal mechanism as shown in Figure 18.

Using a slow-acting press, apply pressure to the press-

on tool and press the mechanism onto the shaft until it

sets against the spacer. To prevent damaging the

mechanism and/or spacer, the force applied to the

press-on tool to press the mechanism onto the shaft

should not exceed 3000 pounds.

FIGURE 16.

HOOK SUSPENSION.

FIGURE 17.

CENTRIFUGAL MECHANSIM PRESS-ON TOOL. 27

27