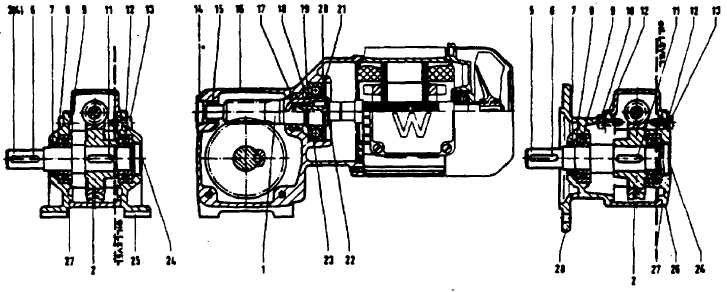

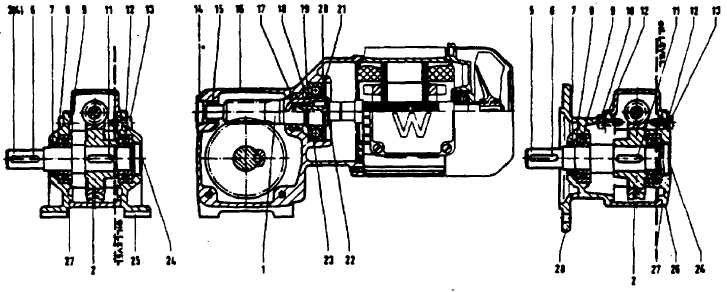

OIL FILL INSTRUCTIONS

S30 DT71DT80

Right Angle (Worm) Gearmotor

Right Angle (Worm) Gearmotor

The S30 and SF30 gearmotors are filled by Eurodrive

with a synthetic oil, Mobil Oil SHC 634.

The synthetic oil has an extremely long life at high and

low temperatures (temp. range 170° to -5° F).

The oil does not have to be changed during the life of

the gear reducer, unless the gear reducer components

wear severely or the oil gets contaminated. The unit,

therefore, does not have an oil fill plug or drain plug.

Oil Filling The units are filled by removing the indicated

side of the reducer. Procedure:

1. Remove Bolt #13. (4 on one side)

2. Remove the section #25 or #26.

Note

The oil is filled to the level shown below (see dotted

line).

When the unit has to be taken apart, drain the oil so it

can be used again if necessary.

Under one (1) of the bolts #13, a copper washer can be

found. It is important to install the washer again, in the

proper place, to prevent oil leaks around the bolt.

When a synthetic oil cannot be obtained, a 140W gear

oil can be used temporarily. The temperature range of

the 140W gear oil is 104° F to 32° F.

C-FACE MOTOR ADAPTERS - TYPE "LP"

C-Face adapters are designed for standard AC motors and DC motors with similar weight. If a large DC motor has to be

Installed on a C-face adapter the motor base must be adequately supported to remove the stress from the housing.

Excessive stress can cause housing failure.

For additional information about the frame sizes recommended please refer to the Eurodrive Constant Speed Catalog.

SCOOP MOUNTS

Maximum motor frame sizes recommended for scoops are listed in the Eurodrive Constant Speed Catalog. If a motor

larger than recommended has to be Installed, support the scoop, this will prevent misalignments and premature failure of

components.

SHAFT MOUNTED REDUCERS

MODELS KA, KAF, SA, SAF, FA, FAF.

For the above listed shaft mounted reducers, Eurodrive recommends:

The use of a light coating of NEVER-SEEZ (or equivalent) on the output shaft.

The NEVER-SEEZ lubricant may prevent a rusting and fretting corrosion between the hollow reducer shaft and the shaft

of the driven machine. The lubricant will allow the shafts to be disassembled when necessary.

14