TM 10-4320-317-13

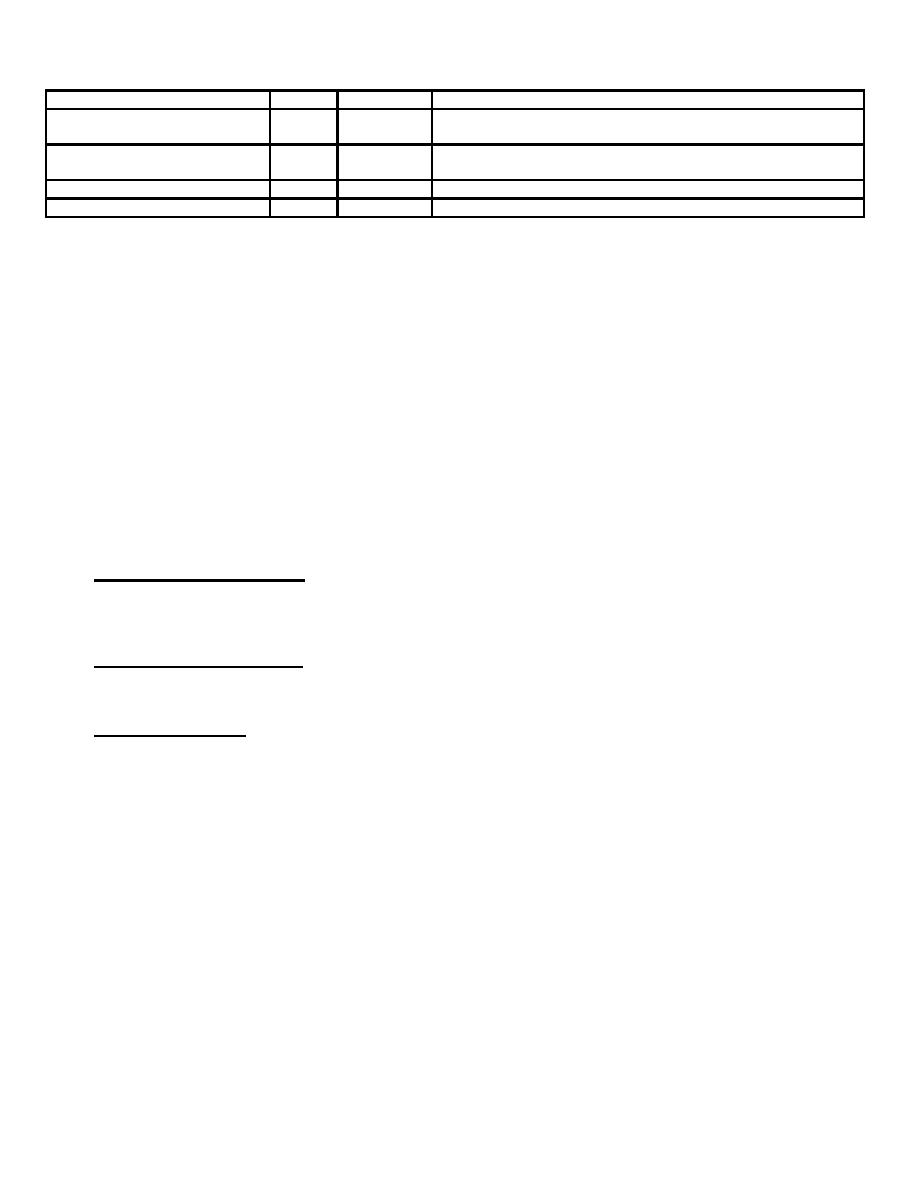

Table 4-4. Distribution Points - (Cont)

Item

Qty

Size

Inspection

Reducer, quick-disconnect

2

4 in. X 2 Make sure cam arms move freely. Check for damaged or

in.

missing gasket. Check reducers for stripped or worn threads.

Wye-connection, quick-

6

2 in. X 2 Make sure cam arms move freely. Check for damaged or

in. X 2 in. disconnect missing gasket.

Centrifugal Pump Unit

2

125 GPM

Refer to applicable technical manual.

Swivel, hose

4

2-inch

Check for cracks or breaks

h. Deprocessing Unpacked Equipment.

(1) Remove all tape and packing film, if any, from equipment.

(2) Remove all plastic tie-wraps, if any, necessary to place the equipment in operation.

(3) Remove all shipping tags from components and retain for future reference.

(4) Refer to DA Form 2258, Depreservation Guide for Vehicles and Equipment, packed with the equipment. The

depreservation guide explains what was done to the

i.

Report damage or discrepancies in accordance with DA PAM 738-750 for Product Deficiency Report (SF368).

Section III. PREPARATION FOR STORAGE AND SHIPMENT

4-7. Administrative Storage. This paragraph contains information on administrative storage procedures. If additional

information is required, refer to AR 750-1.

a.

Storage Length and Readiness Placement of equipment in administrative storage should be for short periods of

.

time (1- 45 days) when a storage of maintenance efforts exists. Items should be in mission readiness within 24

hours or within the time factors as determined by the directing authority. During the storage period, appropriate

maintenance records will be kept.

b.

Prior to Placing Unit in Storage. Before placing equipment in administrative storage, current maintenance services

and Preventive Maintenance Checks and Services (PMCS) should be completed, shortcomings and deficiencies

should be corrected, and all Modification Work Orders (MWOs) should be applied.

c.

Storage Site Selection. Inside storage is preferred for items selected for administrative storage. If inside storage

is not available, the sites selected should provide required protection from the elements and allow access for visual

inspection when applicable.

4-8. Preparation of TWDS for Storage. Perform storage procedures for the 600 GPM pumping assembly, 125 GPM

pump, hypochlorination unit, and storage assembly. Refer to applicable technical manuals.

4-7