TM 10-4610-240-24

TM 08580C-24/2

TO 40W4-13-22

3-68. BRAKE ASSEMBLY MAINTENANCE (MODEL WPES-1).

This task consists of:

a.

Removal

b. Disassembly

c.

Cleaning

d. Inspection

e.

Repair

f. Assembly

g.

Installation

INITIAL SET-UP:

Tools Required

General Mechanics Tool Kit (Appendix B, Section III, Item- 4)

Stiff-Bristled Brush (Appendix B, Section III, Item 3)

Soft-Bristled Brush (Appendix B, Section III, Item 3)

Brake Spring Tool (Appendix B, Section III, Item 3)

Hand Grease Gun (Appendix B, Section III, Item 3)

Materials/Parts Required

Solvent, drycleaning (Appendix C, Section II, Item 28)

Grease (Appendix C, Section II, Item 15)

Rags, wiping (Appendix C, Section II, Items 23)

Lockwasher (2) - 500358-17

Lockwasher (8) - 500357-13

Seal, Oil (2) - M16HH100

Equipment Condition

Tire and wheel assembly removed (para. 2-99)

Trailer disconnected from towing vehicle (TM 10-4610-240-10).

Hub and drum assembly removed (para. 2-100).

General Safety Instructions

WARNING

Using drycleaning solvent incorrectly can cause injury or even death.

Using compressed air can be dangerous.

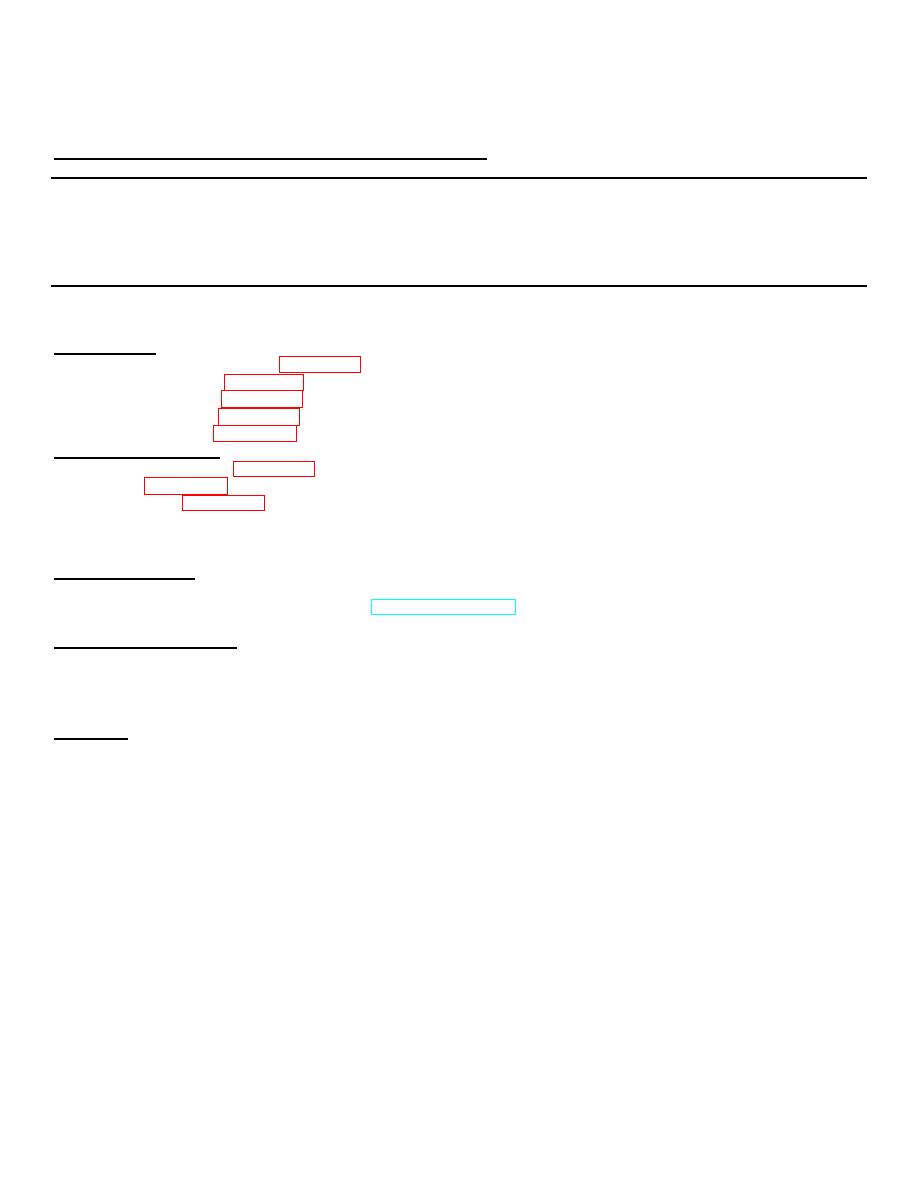

REMOVAL

a.

Remove cotter pin (3) and clevis pin (4). Separate slack adjuster (2) from air chamber pushrod clevis (5).

b.

Remove lockring (6) and slack adjuster (2) from camshaft (14).

c.

Remove four nuts (13), four bolts (7), cover plate (8), and tapered bushing (9).

d.

Remove eight nuts (15), washers (16), and bolts (18).

CAUTION

Pull brake assembly straight out from trailer. Any vertical or side-to-side

movement can cause damage to splined end of camshaft.

NOTE

Cover plate and tapered bushing might slide off camshaft when camshaft is pulled

through camshaft bracket.

e.

Remove brake assembly (17), tapered bushing (11), and cover plate (12) from axle (1) and camshaft bracket

(10).

3-348