TM 10-4610-241-10

TO 40W4-13-41

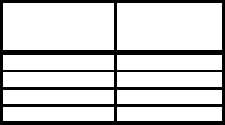

Table 3-2. Operator Troubleshooting (ROWPU) - cont.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5.

PRODUCT WATER FLOW READING RISES ABOVE 16 GPM (FRESH/BRACKISH), 12 (SEAWATER) AND

CANNOT BE LOWERED USING REGULATE PRODUCT FLOW VALVE cont.

CONDITION

FRONT

SAMPLE

REAR

SAMPLE

CAUSE

1

NORMAL

NORMAL

Vessel operation OK

2

HIGH

NORMAL

Leak at front end connector preformed packing*

3

NORMAL

HIGH

Leak at rear end connector Preformed packing*

4

HIGH

HIGH

Leak at front and rear end connector Preformed packing

and/or R.O. element interconnector Preformed packing*

*Condition could also be caused by defective R.O. element.

Step 2. Check product water flow from each R.O. vessel.

a.

Use same method as in Step 1 to collect product water sample, but this time measure the time in

minutes it takes to fill a 3-gallon bucket with product water from each vessel. Divide the number of

minutes by three.

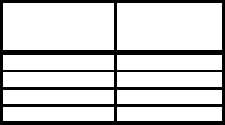

b. Make a chart like the following:

R.O. Vessel

Flow in GPM

1 (-Top)

4

2

3

3

2

4 (Bottom)

1

c. Examine your chart for a similar pattern. Flow rate should get smaller from top to bottom.

(1) If any R.O. vessel does not follow this pattern, disassemble that vessel and replace defective

items (para. 3-4).

MEASURED TDS

3-7