TM 10-4610-241-24

TO 40W4-13-42

3-44.

HIGH PRESSURE PUMP (R.O. PUMP) REPAIR (MODELS WPES-10, WPES-20,

AND WPES-30) - continued.

c.

Cleaning.

WARNING

Dry cleaning solvent, PD-680, C1 II, is highly toxic and can ignite

organic materials, nitrates, carbides and chlorates. Wear eye, skin and

respiratory protection. Use in well-ventilated area.

(1)

Clean large parts (power frame, fluid cylinder, etc.) with rags and cleaning solvent.

(2)

Clean all small items (bearings, bolts, etc.) by dipping in cleaning solvent.

d.

Inspection.

(1)

Fluid Cylinder (15). Inspect cylinder for cracks, gouges, stripped threads and other

visible damage.

(2)

Valve Seats (24 and 40). Check valve seats for wear, scratches, stripped threads and

other damage.

(3)

Plungers (25). Check for cracks and chips in ceramic coating of plungers and

damaged/stripped connecting nut or nut retainer.

(4)

Miscellaneous hardware. Check all remaining hardware for cracks, damaged threads,

excessive wear, corrosion, deformation and other damage making the item unserviceable.

e.

Repair.

(1)

Replace lockwashers, gaskets and preformed packing.

(2)

Replace defective and excessively worn components.

f.

Assembly.

(1)

Place fluid cylinder (15) on a clean work bench and

follows:

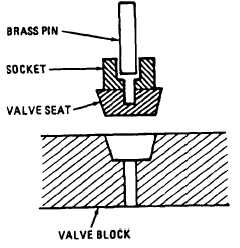

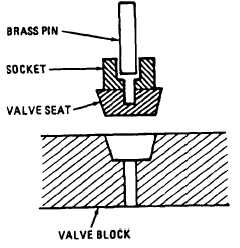

(a)

Position valve seats (24 and 40) on top of

valve seat bores.

(b)

Position a socket (slightly smaller then

valve seat) on top of valve seat.

(c)

Position a large diameter brass pin on

inside surface of socket.

(d)

Tap pin with hammer until valve seat is

firmly lodged in valve block.

install valve seats (24 and 40) as

3-248 Change 1