SPANMASTER TROLLEYS

The Spanmaster line of monorail trolleys has been designed with an eye first to quality and service- ability and secondly

to economy for the different capacities and service factors for which the various trolleys are designed and offered.

WHEELS: All wheels are made from high alloy forged steel. Treads are accurately machined and hardened to 425-480

Brinell.

BEARINGS: All trolley wheels are equipped with first quality precision ball bearings which are lubricated and sealed at

assembly. This feature eliminates the necessity for periodic checks and lubrication of the wheel bearings and assures

satisfactory bearing life even under adverse operating conditions. For special conditions where unusual factors are

present the wheel assemblies can be equipped with pressure lubrication fittings. Spanmaster wheel assemblies are

designed to permit replacing a bearing, if necessary, without having to replace the entire wheel, bearing and axle

assembly.

SIDE ROLLERS: Several of the heavier series of trolleys are available equipped with lubricated and sealed precision ball

bearing, heavy, heat treated side guide rollers. These side roller trolleys are generally recommended for use on high

speed, high service, power driven equipment. When used in this manner this type of trolley can materially extend the life

of the rail by eliminating the scuffing action of the wheel flanges on the edge of the rail. Where there are curves in the

system they also serve to guide the trolleys into and out of the curves when operating at high speeds.

TWO WHEEL TROLLEYS: It will be noted that each trolley series includes a two wheel trolley. These two wheel trolleys

are the basic assembly used to make up the various four wheel trolleys. They may also be used in pairs to mount on

carriers, racks, etc., and suitable fittings are shown for that purpose. These two wheel units must not be used singly to

carry a load since they will not operate properly if so used.

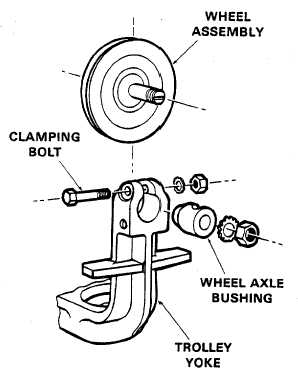

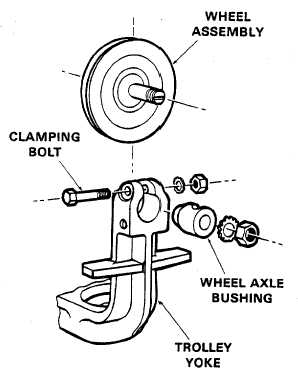

TROLLEY WHEEL MOUNTING

In the interest of easy installation and maintenance it is

highly desirable that trolley wheels be easily in- stalled

or removed while the trolley is on the rail. Spanmaster

trolleys are equipped with a unique feature which

permits this interchangeability of wheels without

removing the trolley from the rail. In the accompanying

sketch you will notice that there is a "Wheel Axle

Bushing" which fits the bore in the trolley yoke and also

accommodates the axle of the wheel assembly. This

bushing is prevented from slipping or turning by the

clamping bolt which also engages a notch in the bushing

to insure and maintain correct wheel gaging. To remove

a wheel with the trolley on the rail the hexagon nut and

lockwasher are removed from the axle and the clamping

bolt removed from the yoke. The bushing is then

withdrawn from the yoke bore as shown. With the axle

bushing removed the wheel axle will readily slip upward

thru the slot in the top of the yoke thus freeing the wheel

assembly from the trolley. Replacing the wheel simply

involves the above procedure in reverse. This

interchangeability of wheels is quick and simple and can

be accomplished without the use of any special tools or

devices.

DIMENSIONS ARE FOR ESTIMATING PURPOSES ONLY. REQUEST CERTIFICATION FOR CONSTRUCTION.

Copyright 1978

A DIVISION OF JERVIS B. WEBB COMPANY

Page 16.2

Jervis B. Webb co.

739 MOORE ROAD, AVON LAKE, OHIO 440121

0-1-80