TM 55-1930-209-14&P-13

Condition

Possible Cause

Suggested Action

c.

Internal leakage in

c.

Remove and replace activating

activating cylinder

cylinder

4.

Anti-2-block system malfunc-

a.

Bad fuse in power circuit a. Replace fuse

tioning

b.

System malfunctioning

b.

Troubleshoot system

3-19

Maintenance procedures

3-19.1 General. Maintenance procedures for the bow crane system follow. Repair concerns lubricating, disassembling,

repairing, replacing, and reassembling equipment using repair parts listed in TM 55-1930209-14&P-18. No special tools

are required. A list of tools and test equipment is in TM 551930-209-14&P-18.

When performing maintenance, be sure to observe safety precautions in this manual, the manufacturers'

manual/instructions, and the following general shop practices:

a.

Always use new seals and gaskets, same as original, when reassembling components that have been

disassembled for repair. Carefully install so as not to damage during assembly.

b.

When replacing gaskets, make sure all mating surfaces are clean and free of old gasket material, adhesive oil, or

grease. These precautions will ensure a leakproof joint.

c.

When replacing O-ring seals, make sure all surfaces are thoroughly clean and free of grit, dirt, and foreign

material. Prior to installation, apply a thin coat of protective lubricant to O-ring for ease of assembly. Protect the

O-ring by applying tape over threads, sharp corners, or edges.

d.

When replacing or repairing electrical components, follow proper precedures for soldering or crimping

connections. Check all groundings. Check that all current-carrying members are properly insulated to avoid

short circuiting. Check for abrasion and chafed insulation on wires and cables. Repairwith tape or replace as

necessary.

e.

When replacing bearings, follow procedures in TM 9-214. Lubricate bearings with recommended lubricant.

When installing bearing on shafts, apply pressure to inner race. When installing bearings in housing, apply

pressure to outer race.

f.

Weld in accordance with TM 9-237 and MIL-STD-1261. Welding can be used to repair cracks and breaks in

steel parts such as bracket, panels, and light framework. Weld only when replacement parts are not available

because of a chance of failure later.

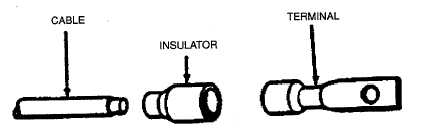

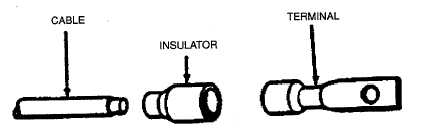

(1) Strip cable insulation equal to depth of terminal well.

(2) Slide insulator, if used, over cable.

(3) Insert cable into terminal well and crimp.

(4) Slide insulator, if used, over crimped end of terminal.

Figure 3-9. Replacement of Crimped Terminals

3-17