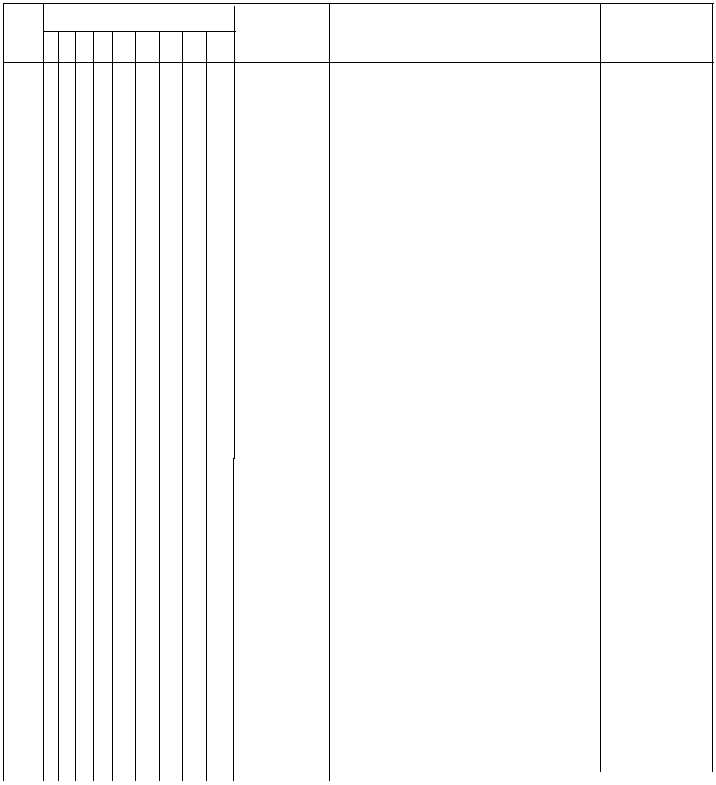

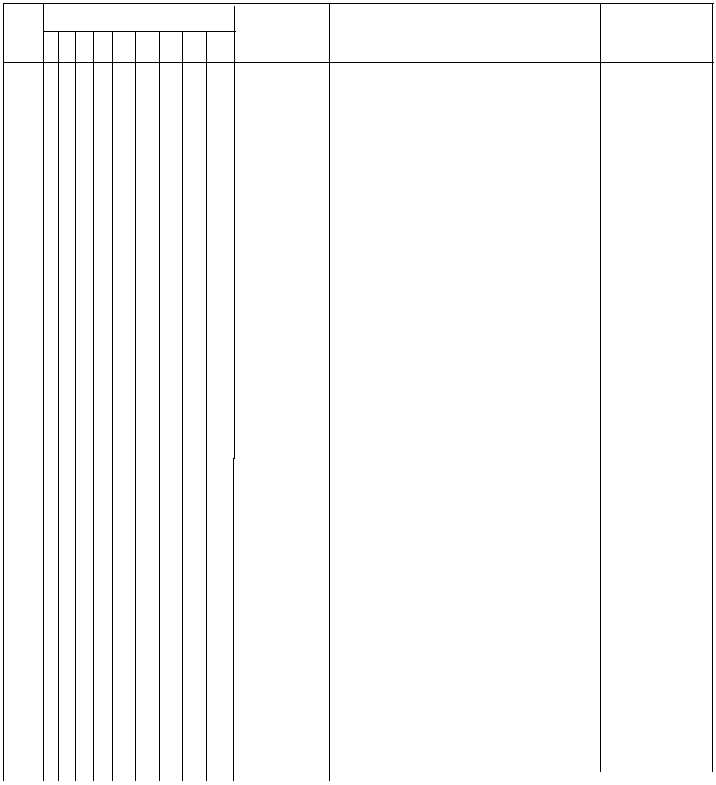

TM 55-1930-209-14&P-14

Table C-1. Preventive Maintenance Checks and Services for Anchor, Mooring, & Towing Equipment

(Continued)

B-Before

D-Daily

Q-Quarterly

D-During

W-Weekly

S-Semiannually

A-After

M-Monthly

A-Annually

Item

INTERVAL

Item

Procedures Check For

Equipment Is Not

No.

To Be

And Have Repaired Or

Ready/Available

B D A D W

M

Q

S

A

Inspected

Adjusted as Necessary

*

*

*

g

Apply multipurpose, water-resistant

grease (MILG-24139) on anchor cable

fairleader rollers, and all exposed,

unpainted surfaces.

CAUTION

During anchor retrieval, If winch panel

circuit breaker trips several times dur-

lng operation, this may indicate a

wrong recovery method. Continuing

to operate winch under these conditions

will damage winch motor.

*

*

h. Check condition of cable as it is pulled

Drum cable is

into drum. If cable is frayed, smashed, or

frayed, smashed,

cut, note location on drum and notify shift

or cut.

leader or bargemaster so repairs or

replacement can be done.

*

*

*

i.

Remove rust and corrosion. Clean and

touchup all painted surfaces in accor-

dance with TB 43-0144.

*

j.

Make sure power panel 3 (120 Vac) cir-

cuit breaker 11P13 is closed (ON) to

provide heat to electric motors and

brakes to combat moisture and corro-

sion.

*

*

k

Visually check electric winch motors,

Wiring is frayed

motor controllers, and wiring for damage

or damaged.

or malfunction. Report deficiencies to

shift leader or bargemaster for corrective

action.

*

l.

Check winch manual brakes to assure

Brake bank is

brake bank is properly fastened and not

excessively

excessively worn.

woM.

*

m. Check and clean all electrical comipo-

nents and wiring.

C-7/(C-8 blank)