DECKMASTER

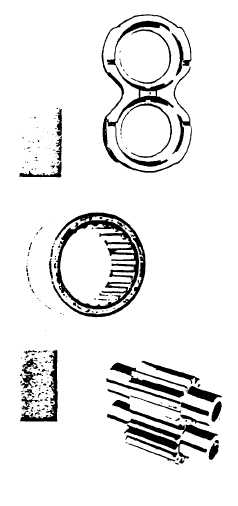

Thrust plate

COMMERCIAL'S original "pressure-pocketed" thrust

plates are another built-in feature of Model 15H pumps

and motors and serve a most important function. By

"pressure-pocketing", a dynamic seal is created which

prevents oil under high pressure from flowing toward the

low pressure side of the thrust plate. Therefore, a

positive seal is created which contributes to volumetric

efficiency of pumps in excess of 90%. These floating

type thrust plates exert a force at all times against the

small sealing area at the gear faces. The small loss of

mechanical efficiency due to friction between thrust

plates and gear faces results in considerable gain in this

volumetric efficiency.

Bearings

Bearings are built into COMMERCIAL Model 15H

pumps and motors to maintain positive shaft and gear

alignment. Anti-friction bearings are designed to absorb

all radial and thrust loads always present to the

unbalanced loading conditions inherent in gear type and

motors. Two heavy duty, anti-friction inboard gear

journal.

ings

are

provided

for

each

gear.

COMMERCIAL also provides a ruls6¢d outboard

bearing, a ball bearing type, for all pumps and motors.

Bearings are fit to the gear hubs, not to the drive shaft.

Because gear hub is integral with the gear, larger

bearings, necessary for satisfactory operation at 2000

psi, are possible. Such gear hub construction

permits more accurate machining held to closer

tolerance.

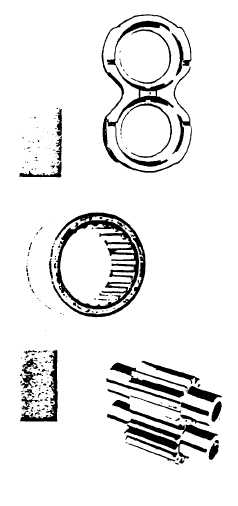

Gears

For high volumetric efficiency of gear type pumps and

motors, complete sealing between all gear tooth contact

surfaces must be maintained. As operating pressures

increase, this contact becomes more difficult to

maintain. COMMERCIAL found that gears which were

obtainable on the open market did not have tooth

surfaces smooth and sufficiently accurate for high

efficiency operation at 1500 psi and higher. Gear

surfaces are precision finished, each pair. matched

perfectly. COMMERCIAL manufactures gears for all

their pumps and motors and makes every effort in

design and manufacture to assure producing gears

which will give the quietest and most efficient operation.