TM 10-4610-232-12

(2) RO Vessels (2). The pressurized feed water is discharged through a high pressure hose to a manifold

connecting the top two RO vessels. pressurized water enters the top two vessels and, as it passes across the membrane

sheets, some of the water passes through and is collected in a central product water tube. The feed water, now

containing a higher concentration of dissolved solids (higher TDS), discharges through an end fitting into a high

pressure pipe which directs the water back tO the inlet end of the corresponding lower RO vessel. The water similarly

passes across the membrane sheets within the lower vessels, producing additional product water,

(3) System Pressure Control Valve (5). The remaining feed water leaving the bottom RO vessels is now waste

water and contains concentrated salts, From each vessel it passes through an orifice to decrease the pressure and then

is combined to pass through the high pressure control valve and another orifice. This valve controls the working

pressure of the system. By controlling the pressure of the system, the valve controls the amount of product water made.

A high pressure switch (4) limits the pressure to 900 psig (6205 kPa).

(4) Product Water. The product water from each vessel is collected in a header and piped to the outlet. An in-line

TOS meter (6) and portable TDS meter monitor dissolved solids content to assure that product water meets potable

water standards. Just before the outlet, calcium hypochlorite is added to disinfect the product water. The chlorinated

product water is called potable water. When the TDS meets potable water standards, the product water hose is

manually inserted in a storage tank. When the product water does not meet potable water standards, the hose is

directed to waste. A pressure switch (7) shuts down the ROWPU if hose blockage causes high pressure.

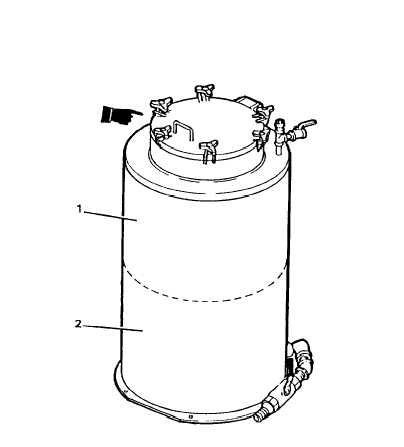

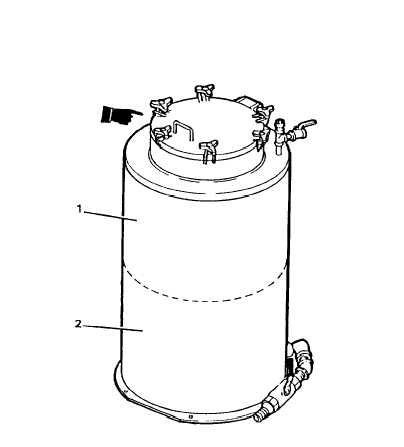

e. NBC Filter (Figure 1- 14). The ROWPU can decontaminate waters which contain nuclear, biological or chemical

agents. The feed water filters and the reverse osmosis elements remove most of these agents, however, safe levels are

not assured. When decontaminating NBC contaminated water the product water is additionally passed through the

NBC filter for final agent removal. After filtration, the water is chlorinated and is potable. The filter is connected by

jumper hoses when required, The filter contains a layer (bed) of activated carbon(1) and a layer (bed) of ion exchange

resin beads (2), The NBC agents are removed by these materials. The carbon and resin beads are replaced after each

100 hours of water production to assure that there is always capability to absorb NBC materials.

Figure 1-14. Operation of NBC Filter

Change 2 1-23