TM 10-4610-232-34

2-6. STUD AND THREAD REPAIR. This task covers:

a. Repair.

Tools, see TM 10-4610-232-12, Appx B,

Sec II, Ref Code (No.)

Tool Kit, General Mechanics Automotive (1)

Screw Thread Repair Kit (4)

Tap and Die Kit (4)

Micrometer (4)

Vernier Caliper (4)

Hand Drill (4)

Screw Extractor Kit (4)

Materials/Parts:

Transmission Oil

WD40 (Appx B, Sec II, Item 75)

Dry Cleaning Solvent (Appx B, Sec II, Item 32)

Rags, Wiping (Appx B, Sec II, Item 58)

Equipment Condition:

ROWPU Shutdown.

General Safety Instructions:

WARNING

Observe specific Warnings and Caution in the text.

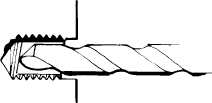

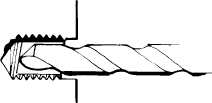

a. Repairing studs or screws — broken flush. (Refer to Figure 2-3, View A.)

(1) Center punch broken stud or screw.

CAUTION

Be careful not to drill into the component when repairing studs or screws.

(2) Drill into broken stud or screw using a drill bit 1/16 in. less the diameter of the broken stud or screw.

(3) Using a screw extractor, remove broken stud or screw.

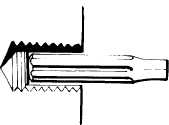

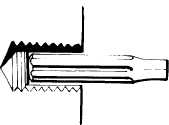

b. Removing studs or screws that have not broken flush. (Refer to Figure 2-3, Views B and C.)

(1) Spray broken stud or screw with WD40 and allow it to penetrate.

(2) Clamp broken stud or screw using pliers.

VIEW A

VIEW B

VIEW C

Figure 2-3. Removing or Repairing Studs or Screws

2-80