TM 10-4610-240-10

TM 08580C-10/1

T.O. 40W4-13-21

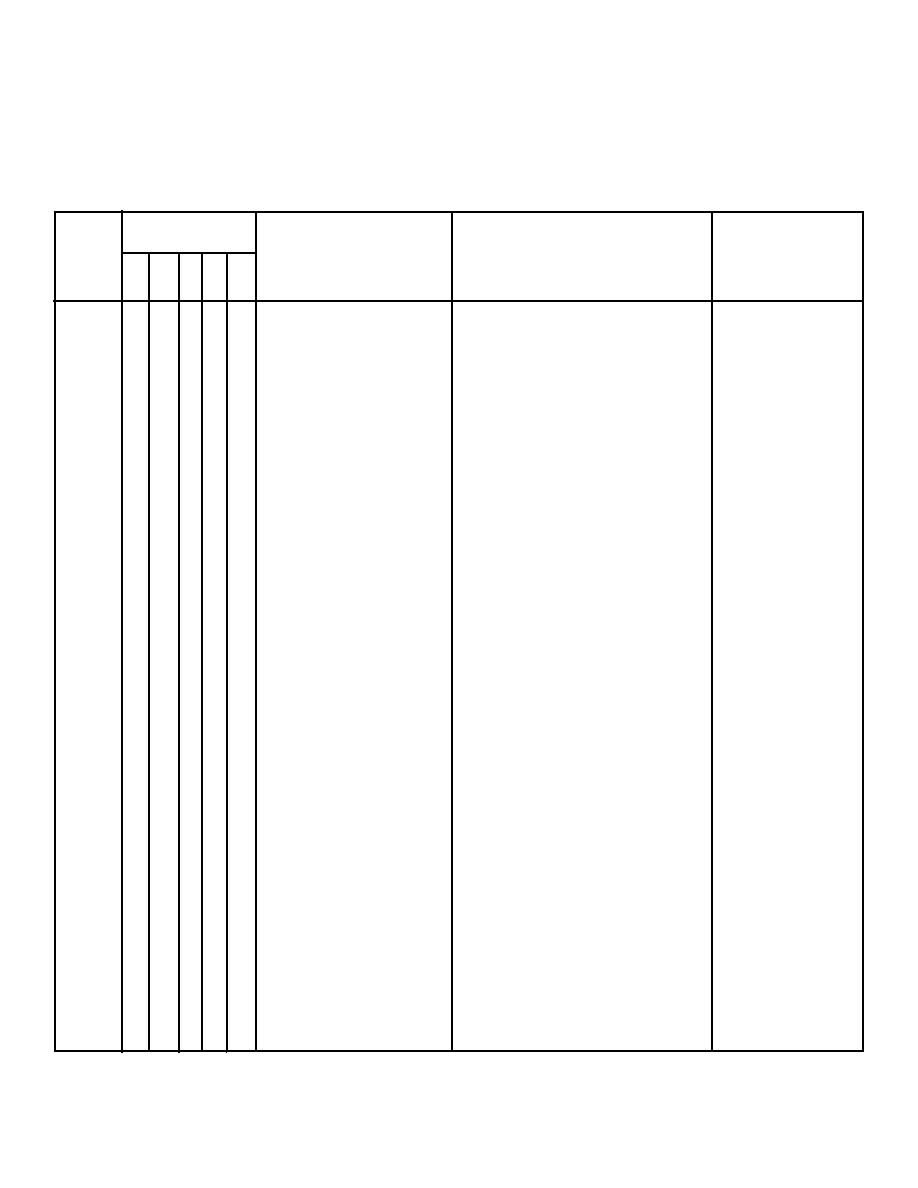

Table 2-3. (ARMY) Operator/Crew Preventive Maintenance Checks

and Services (Unit) - Continued

B - Before Operation

D - During Operation

A - After Operation

W - Weekly

M - Monthly

INTERVAL

Item to be

Procedures

Equipment is

ITEM

Inspected

Check for and have repaired

not ready/

NO.

B

D

AWM

or adjusted as necessary.

available if:

36

Special tools:

Inspect for bent shafts and

paddle, R.O.

stripped threads. Replace

element puller,

damaged tools.

bulb puller

37

Circuit breakers

Inspect for cracked or broken

Any circuit breaker is

parts. Before connecting

damaged or will not

generator set, check for free

move easily.

movement of handle. Inspect for

signs of burning or arcing.

38

Water testing

Check for cracked or broken

equipment:

glass. Check to see that all

beaker, graduated

markings are readable. Replace

cylinder, solution

damaged items.

indicator,

thermometer,

turbidity tube

39

Rupture disc

Before operation, make sure an

An intact rupture

assembly

intact rupture disc is in place.

disc is not in place.

Check for leaks around rupture

There is leakage

disc assembly.

around rupture disc

seat.

40

Pulse dampener

Inspect for broken, corroded, or

There is any damage

missing mounting hardware.

to weldment.

Check for cracks on weldment.

Inspect for leaks.

41

High pressure

Inspect for corrosion. Check for

There is excessive

relief valve

leakage at base of relief valve.

leakage at relief

valve.

42

In-line TDS

Inspect for damage.

Install on

monitor

control panel.

43

Water meter

Inspect for damage or leakage.

Excessive leakage.

Ensure cover is closed when

readings are not being taken.

Ensure that meter reads properly

during operation.

44

NBC Cartridge

Check for leaks at hose/adaptor

Filters

connections. Change NBC

cartridge filters after every 100

hours of use.

2-29