TM10-4610-240-24

TM 08580C-24/2

TO 40W4-13-22

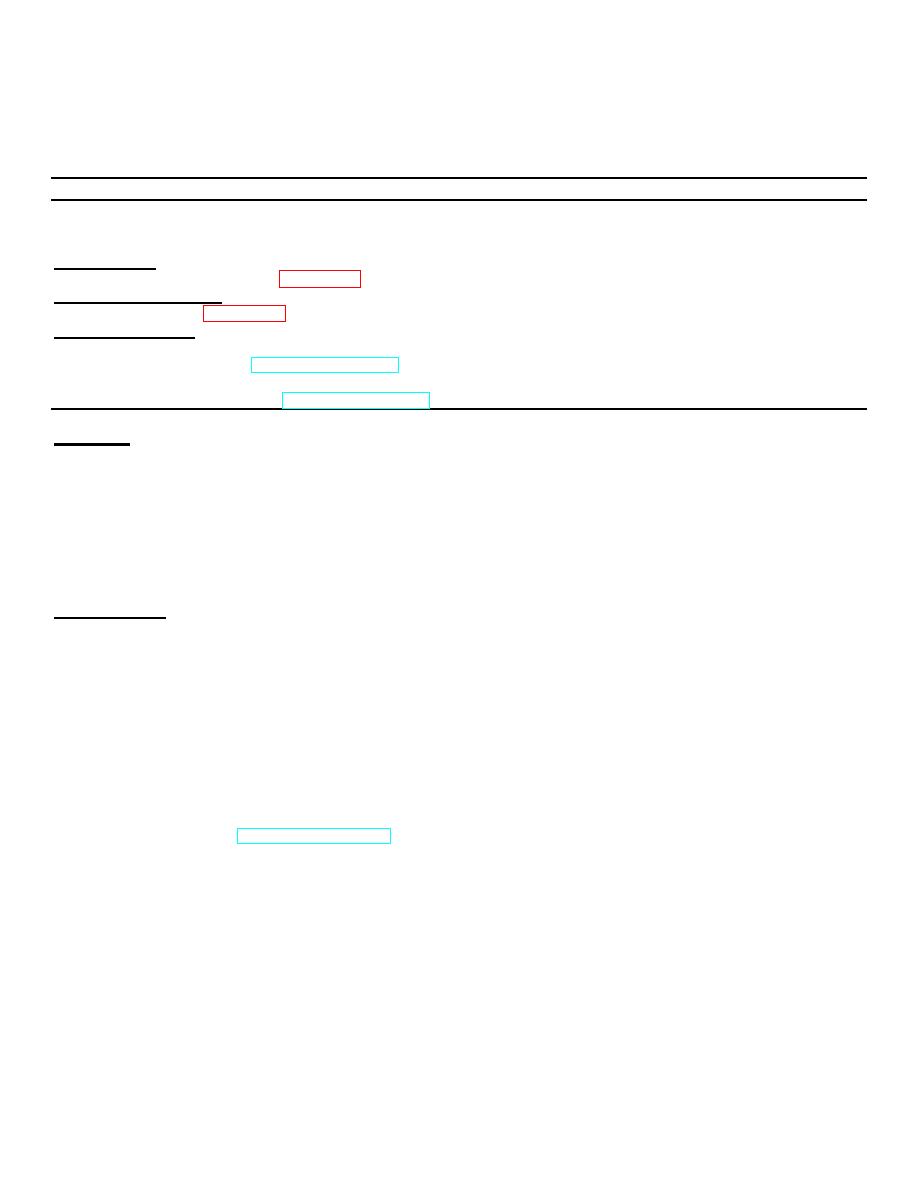

2-58. PRESSURE GAGE (R.O.) MAINTENANCE.

This task consists of:

a. Removal

b. Installation

INITIAL SET-UP:

Tools Required

General Mechanics Tool Kit (Appendix B, Section III, Item 4)

Material / Parts Required

Tape, Anti-seize (Appendix C, Section II, Item 30)

Equipment Condition

Reference

ROWPU shutdown (TM 10-4610-240-10).

Power shutdown (power source manual).

ROWPU piping drained (TM 10-4610-240-10).

REMOVAL

a.

Disconnect three tubes (1, 8, and 9) from distribution block (2).

b.

Remove distribution block (2) from pressure gage (7).

c.

Remove two nuts (3), lockwashers (4), and bracket (5).

c.

Remove pressure gage (7) from front of control panel (6).

INSTALLATION

a.

Apply anti-seize tape to all male pipe fitting threads. Make sure tape is wrapped in same direction as pipe

threads.

b

Position pressure gage (7) in cutout on control panel (6).

c

Position bracket (5) on rear of pressure gage (7) and install two lockwashers (4) and nuts (3).

d.

Install distribution block (2) on pressure gage (7).

e.

Connect three tubes (9, 8, and 1) to distribution block (2).

f.

Operate ROWPU (TM 10-4610-240-10). Check for leaks and proper operation.

2-212