TM 10-4610-241-10

TO 40W4-13-41

2-13. R.O. ELEMENT CLEANING PROCEDURE - cont.

(30)

Disconnect suction hose from backwash pump inlet (figure 2-72).

(31)

Place brine hose in backwash tank to flush citric acid residue from tank and suction hose.

(32)

Close gate valve between backwash tank and backwash pump.

(33)

Reconnect backwash pump suction hose to backwash pump when hose is clean.

(34)

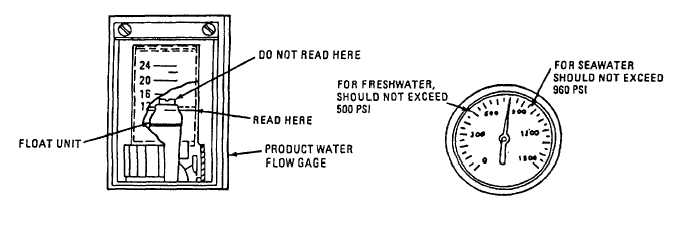

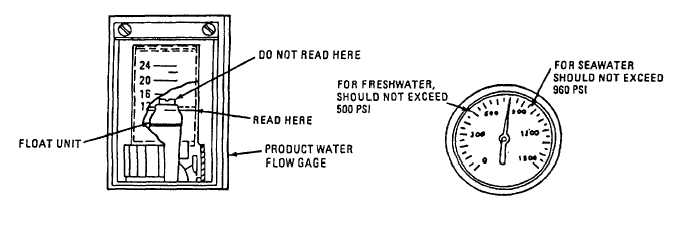

Adjust REGULATE PRODUCT FLOW valve (18, figure 2-5) until PRODUCT WATER FLOW gage

(figure 2-73) indicates under 16 gpm (fresh/brackish water) or 12 (seawater), and R.O. PRESSURE

PSI gage indicates under 500 (fresh/brackish water) or 960 (seawater).

Figure 2-73. Product Water Flow Adjustment.

(35)

Close VENT PRODUCT WATER valve (7, figure 2-46).

(36)

Allow ROWPU to run 3 minutes to flush citric acid from product water hose (figure 2-72) and check

product water TDS (para. 2-15c).

NOTE

If TDS is still over 1000 ppm after cleaning, allowing ROWPU to run longer may lower TDS. Particles

broken loose from the elements during the cleaning process must be flushed from the elements and

related piping. Depending on how dirty the elements were be fore cleaning, 24-72 hours of operation may

be required before TDS decreases to 1000 ppm.

(37)

Only after obtaining TDS level under 1000 ppm, turn CHLORINE PRIME/RUN valve (figure 2-60) to

RUN.

(38)

Wait 5 minutes, then perform chlorine residual and pH test (para. 2-15b).

2-118