ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

0014 00

OPERATOR INSTRUCTIONS

INITIAL START-UP OR START-UP WITH THE SYSTEM FULLY DRAINED

OPERATION UNDER USUAL CONDITIONS

d. Place the chemical injection pump suction tube and return line hose through the cover

hole and into the chemical bucket. Be sure the suction hose inlet rests near the bottom

of the bucket, but not flat on the bottom.

e. Turn the speed dial on the chemical pump to 80, note that the pump has started, and

then rotate the stroke dial to 80.

f. Rotate the black knob on the priming valve one-half turn.

g. Note that the chemical solution is drawing up the suction tube and entering the pump

housing.

h. Rotate the black knob on the priming valve back to its original position when discharge is

noted back to the tank and air is not noted in the suction tube or the pump head. The

pump is now primed.

i. Set the speed dial to 70%.

j. Set the stroke dial to 60%.

5. Set-up the Hypochlorite System as follows:

WARNING

Hazardous chemical dust and/or fumes. Wear the protective face shield, chemical gloves,

and dust mask when handling calcium hypochlorite. Avoid inhaling chemical dust or

fumes. Hypochlorite will give off chlorine vapor, which will burn your nose, throat and

lungs if breathed directly. Keep your head away from top of the bucket while filling.

Inhalation of calcium hypochlorite dust may cause severe chemical burns. Direct contact

with the eyes may cause severe eye damage.

NOTE

When operating on fresh water and brackish water that contains up to 20,000 mg/L TDS

(total dissolved salts) surface water or 2500 mg/L TDS ground water, the product water

flow can initially be assumed to be 25.5 to 26 gpm.

When operating on seawater or brackish water that contains over 20,000 mg/L TDS (total

dissolved salts) surface water or over 2500 mg/L TDS ground water, the product water flow

can initially be assumed to be 20.5 to 21 gpm

Refer to Table 2 for the required free chlorine concentration to be established in the

product water with a product water flow of 25.5 or 21 gpm (depending on the source water

and its TDS as described in the NOTE above). The calcium hypochlorite is mixed in four

gallons of water in the hypochlorite bucket.

Refer to Table 3 through Table 5 at the end of this WP for additional information on the

correct chemical injection pump stroke and speed settings for given product flow rates

and free chlorine required.

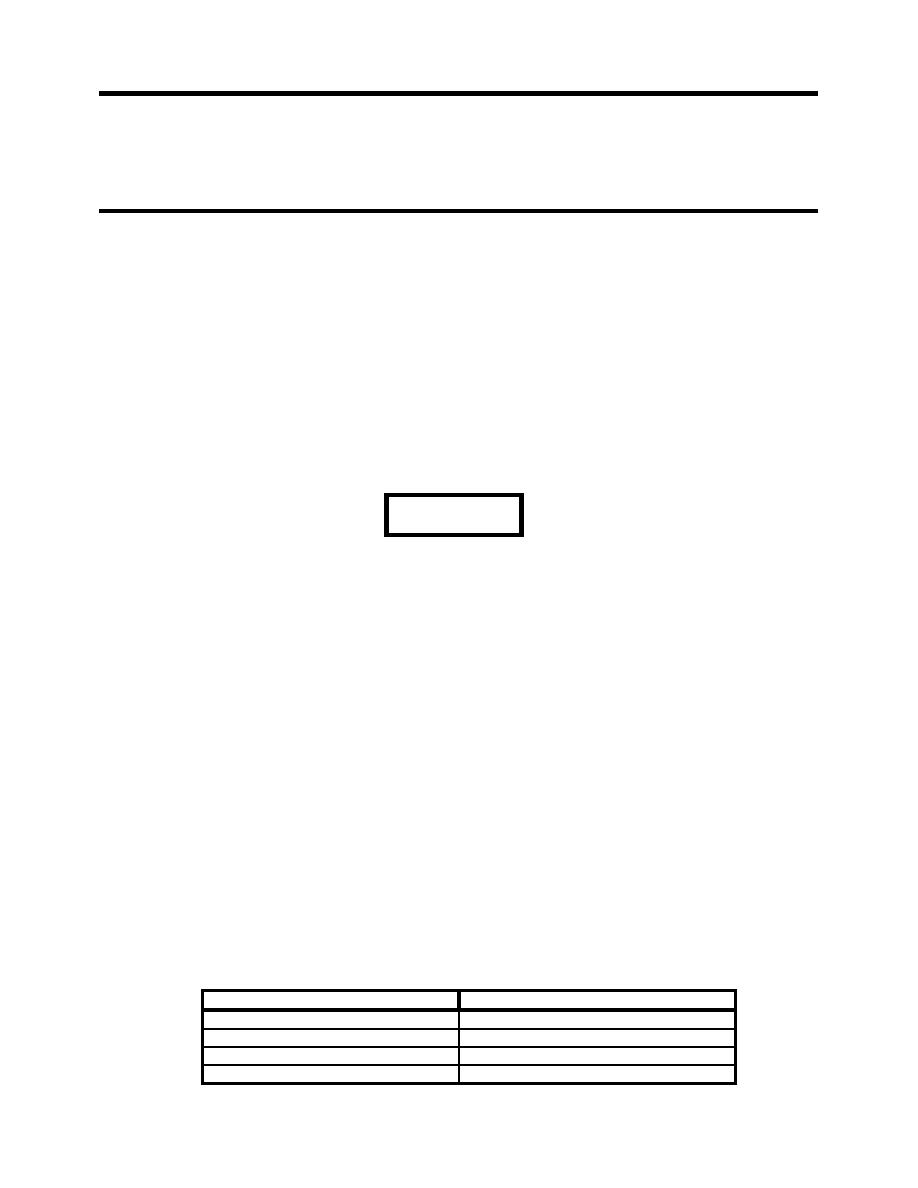

Table 2. Free Chlorine Required, mg/L

Free Chlorine Required, mg/L

Four Ounce (Oz) Packets Required

0.05 1.5 mg/L

1 packet, 4oz each

2.0 3.0 mg/L

2 packets, 4oz each

5.0 mg/L

4 packets, 4oz each

10.0 mg/L

6 packets, 4oz each

0014 00-18