ARMY TM 10-4610-309-14

MARINE CORPS TM10802A-14/1

0021 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

OPERATOR INSTRUCTIONS

MICRO-FILTRATION SYSTEM CLEANING OPERATION UNDER

USUAL CONDITIONS

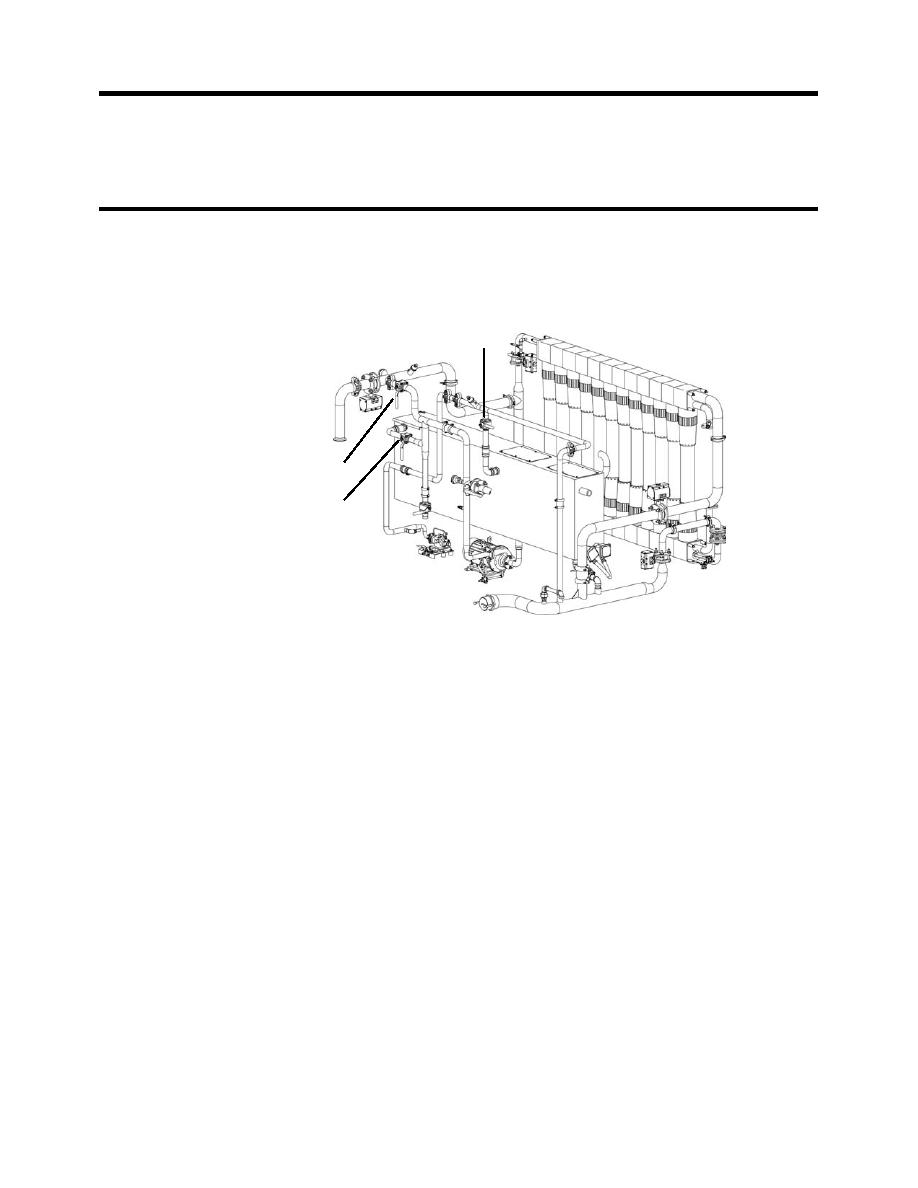

3. Set valves for MF caustic detergent cleaning as follows (see Figure 9 for valve location):

a. Open MF Clean Feed Valve V-704.

b. Open Clean Return Valve V-702.

c. Close Clean Mixing Valve V-703.

d. Be sure that Valve V-705 on Adaptor A-12 is closed (see Figure 5 or Figure 6).

CLEAN RETURN VALVE V-702

MF CLEAN FEED VALVE V-704

CLEAN MIXING VALVE V-703

Figure 9. Valves for MF Caustic Detergent Cleaning.

4. Recirculate the caustic detergent cleaning solution through the MF modules as follows:

a. Set the MF Clean switch to FILL/RECIRC. The RO pump starts to automatically fill the

MF modules and establish recirculation through the MF modules.

b. Turn the Tank Heater switch to AUTO 2. The heaters heat the cleaning solution and

automatically cut off when the temperature reaches 110 degrees F.

c. Check that there is an indication of MF Flow at the OCP display. If not, make sure that

the valves are properly positioned.

NOTE

The CLEAN light flashes during the cleaning cycle and turns off when the cycle is

completed (approximately 26 minutes). The RO pump stops. If the heaters were

on, they also turn off at the completion of the cleaning cycle.

Extended cleaning is required if the transmembrane pressure (TMP) is higher than

the normal reading after the last time the MF was cleaned (3 to 5 psi at 50 to 60

gpm MF Feed Flow).

5. If extended cleaning is required, soak the MF module fibers in the cleaning solution as follows:

a. Set the MF Clean switch to SOAK. This interrupts the clean cycle and leaves the

cleaning solution in the MF modules to soak.

b. Turn the Tank Heater Switch to OFF.

c. Soak for 15 minutes.

d. Set the MF Clean switch back to FILL/RECIRC for one minute.

0021 00-14