ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0052 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

REVERSE OSMOSIS SYSTEM

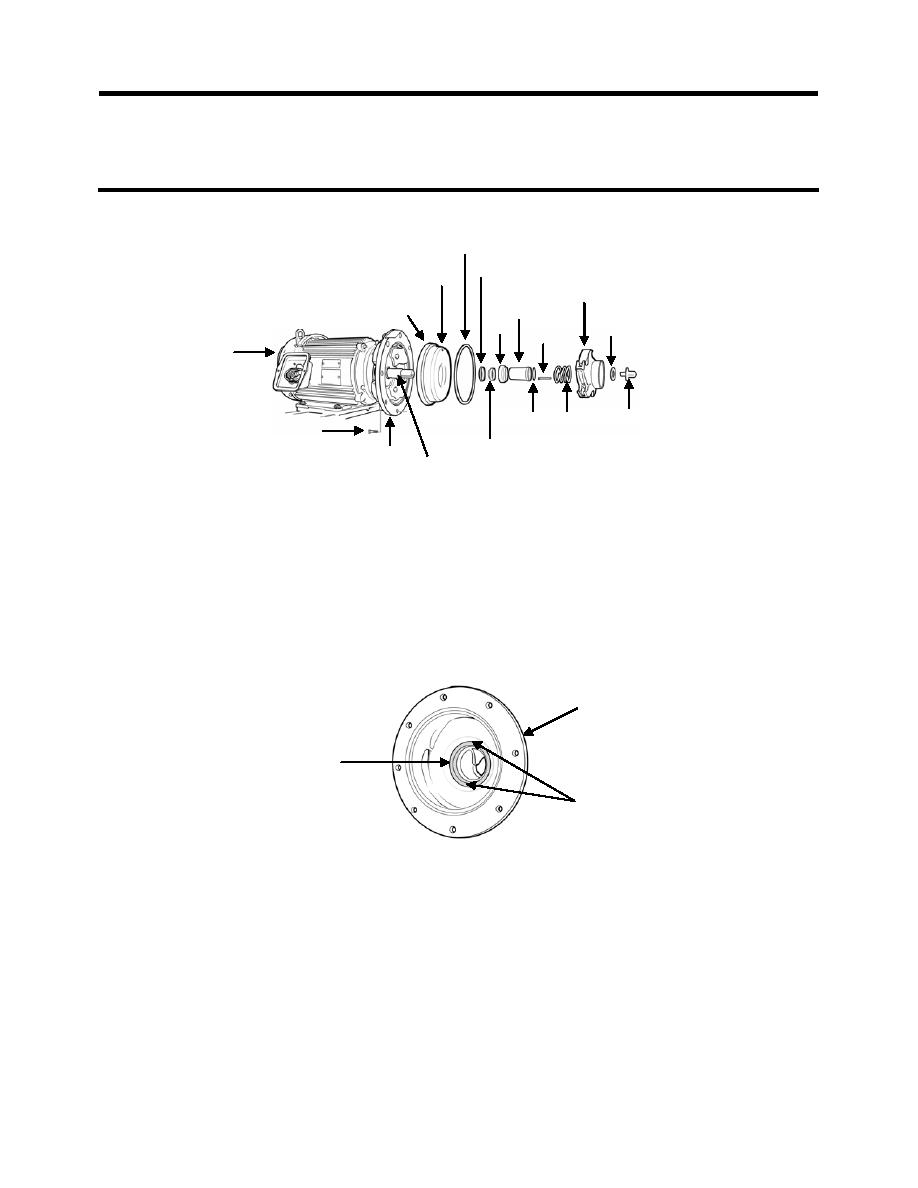

PUMP CASING GASKET

STATIONARY SEAT GASKET

INTERNAL BYPASS HOLE

IMPELLER

PUMP COVER

SLEEVE

SEAL

SCREW GASKET

KEY

MOTOR

O-RING SPRING SCREW

CAP SCREW

STATIONARY SEAT

ADAPTER

MOTOR DRIVE SHAFT

Figure 22. RO Feed Pump Installation.

7. If the wear ring is damaged, replace it as follows (see Figure 23):

a. Drill a hole through the wear ring in two places opposite each other. Be careful not to

damage the pump casing.

b. Crack the remaining ring wall and remove the wear ring.

c. Make sure the surfaces of the new wear ring and the pump casing where the ring is to be

installed are free of burrs. Remove any burrs with a fine emery cloth.

d. Press the new wear ring into place.

e. Evenly drive the ring into place.

PUMP CASING

WEAR RING

EXAMPLE OF WHERE

TO DRILL HOLES

Figure 23. Wear Ring Removal.

8. Reinstall the pump casing as follows:

a. Install a new pump casing gasket on the shoulder of the pump cover.

b. Position the pump casing so that the pump discharge flange points toward you when the

motor is on your left and the pump is on your right.

c. Place the new pump casing onto the pump cover and secure with the eight cap screws.

d. Tighten the cap screws uniformly.

e. Clean off any tape residue remaining on the threads of the street elbow pipes.

f. Wrap antiseizing tape on the elbow pipe threads and screw the street elbow into the

pump casing. Make sure the elbow, drain valve, and hose are facing in the same

direction as the pump discharge flange.

0052 00-29