TM 3-4230-204-12&P

4-8.

SPRAY HEAD ASSEMBLY.

This task covers:

a. Disassembly

c.

Reassembly

b. Inspection/Repair/Cleaning

INITIAL SETUP

Troubleshooting References

Tools and Special Tools

See section IV of this chapter.

General Mechanic's Automotive Tool Kit SC 5180-95-CL-N26

Equipment Condition

Materials/Parts

Spray head assembly removed from container.

Chemical and oil protective gloves (item 8, app E)

May be contaminated with DS2.

Dry cleaning solvent (SD) (item 5, app E)

General purpose detergent (item 4, app E)

General Safety Instructions

Silicone compound (item 13, app E)

NBC protective clothing including mask, hood, and rubber gloves must

Wiping rag (item 12, app E)

be worn when handling equipment exposed to DS 2 until equipment has

been cleaned.

Personnel Required

Protective gloves shall be worn while using dry cleaning solvent.

One quartermaster and chemical equipment repairer MOS 63J or

equivalent MOS or personnel normally assigned in support of this

equipment.

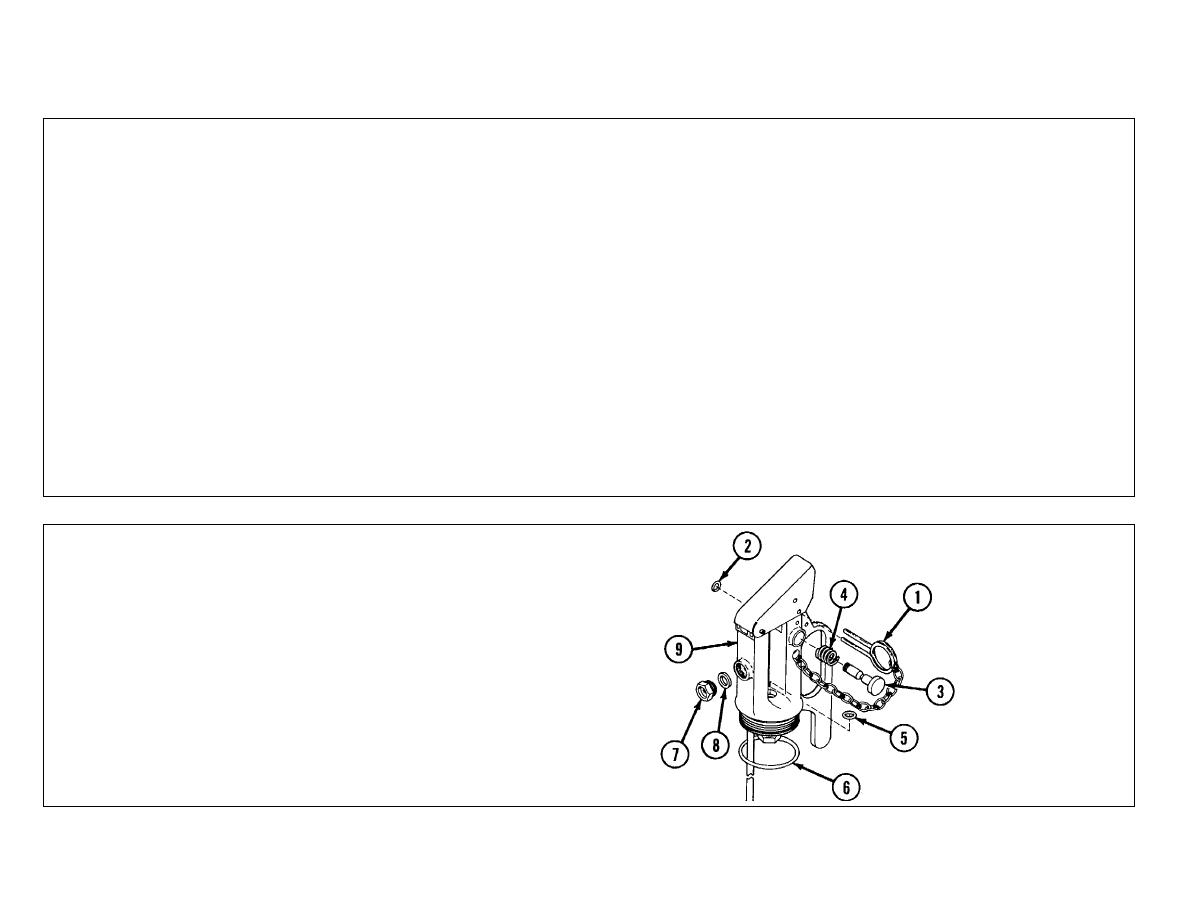

DISASSEMBLY

NOTE

Disassemble only as far as necessary for repair.

Remove parts in order indicated on illustration.

LEGEND

1. Arming pin

6.

O-ring

2. Retaining ring

7.

Nozzle

3. Handle locking pin

8.

Nozzle gasket

4. Helical torsion spring

9.

Spray head body

5. O-ring

4-19