TM 3-4230-237-10

0017 00

OPERATOR'S PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS) - Continued

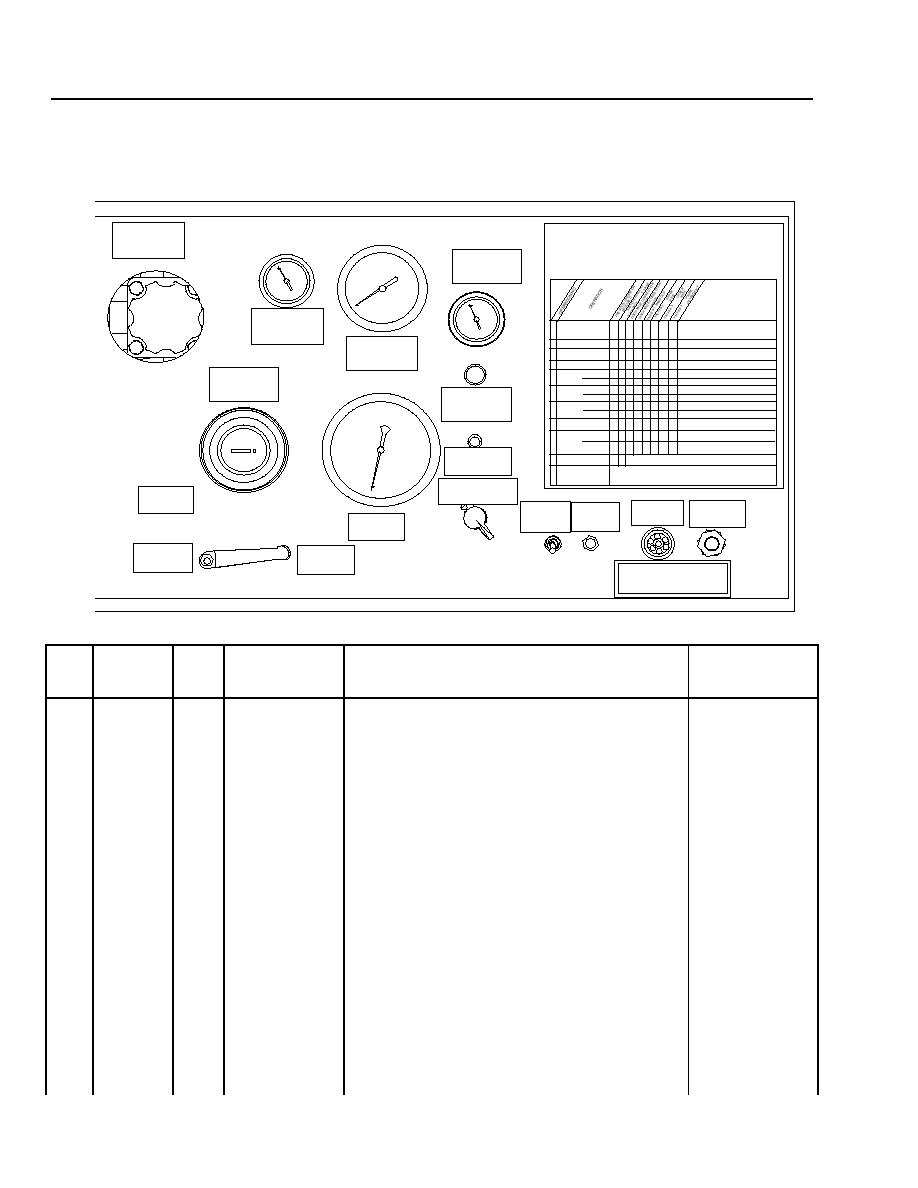

Table 1. During Operation PMCS for M12A1 DED Decontaminating Apparatus - Continued.

STARTINGPROCEDURE

CAUTON:Do not operate pumpdryorwhen discharge pressure is below 60 p.s.i.g.

I

VALVE NO. 3

READ THEMANUAL

UPPEVEEEO.

VAL R R N L

3

1.Checkallvalve settingsbefore starting and close all circuit breakers before starting.

2.If temperature isbelow 40 degrees Fahrenheit,activateenginepre-heater for10 seconds.

3.Turn starting switch to start.

BAVOTEETER

T LTM-

4.Whenenginestarts,releasestart switch to run position.

5.Checkallgages to insure properoperation.

VALVEPOSITION

6.PrimeDetergent Valve#4 must beclosed when Prime-Detergent tank is empty.

O -OPEN X- CLOSED

REMARKS

FUEL

PRIME DRY PU MP

*

**

*TO TANK AGITATOR CONNECT ON E INCH HOSE

FUEL INDICATOR

1.

TURN ON FUELSUPPLY

--

S

ON CAP O

X

X

O

**OPEN FOR 1MINUTE BEFORE STARTING, THEN

START (SEE PROCEDURE)

CLOSE TOHALFWAYFOR REMAINDER OF PRIME

OPERATION (SEE 6 ABOVE)

*

VACU-

2.

FILL TANK WITH WATER

1

S

ON CAP O

X

X

X

*TOAGITATOR CONNECT ONE INCH HOSE

VACUUM GAGE

*

3.

BLEND SLU RRY

2

T

ON CAP O

X

X

X

*TOTANK BLENDER ADD ANTISET

THEN ADD STB.

*

4.

AGITATE SLUR RY

3

T

ON CAP O

X

X

X

*TOTANK AGITATOR

DISCHARGE UPPER REEL

2,3

T

CAPC AP

O

X

O

X

5.

SLURRY

LOWER REEL

2,3

T

CAP CAP

O

O

X

X

HOUR METER

S/

HOURMET-

D ISC HARGE UPPER REEL 1

/T

CAP C AP

O

X

O

X

LOW W IL

LO O

6.

S/

VEE

V

WATER

LOWER REEL

1

/T

CAP

CAP O

O

X

X

OIL PRESSURE

S/

*

**

*FROMHEATER

D ISC HARGE UPPER REEL

1

/T

ON

ON

X

X

O

X

**TOHEATER

TACLE

LIGHT

7.

S/

*

**

*FROMHEATER

H OT WATER LOWER REEL 1

/T

ON

ON

X

O

X

X

**TOHEATER

8.

PUMP WATER ONLY

S/

*

TOHEATER OR OTHER

1

/T

ON CAP

O

X

X

X

*TOHEATER OR OTHER

DISCHARGE FOAM

S/

*

UPPER REEL

1

/T

CAP CAP O

X

O

O

*ADJUSTFOR PROPER BLEND

9.

OR DETERGENT

S/

M AIN

LOWER REEL 1

/T

CAP CAP O

O

X

O

*ADJUST FOR PROPER BLEND

SIYSU IEM

C RC T T

10.

FLUSH SYSTEM

1

S

OPEN TANK DRAIN AND FLUSH TANK THO ROUGHLY, THEN O PEN PUMP DRAIN

AND FLUSH HOSER EELS AND D ISC HARGE CONNECTIONS (SEE MANUAL)

B R EA K ER

11.

SHUTDOWN PROCEDURE

TURN START SWITCH TOOFF POSITION.

CAP ALLPIPES AND CLOSE ALL VALVES EXCEPT PUMP DRAIN VALVE.

OPEN ALLCIRCUIT BREAKERS.

IGNITISTOPITCH

ON SW

OPPN

OE -

STOP

RUN

START

ENGINE

PRIR EAT

C -HUIT

EC

RETURN FUEL

FUEL OUT

PRE-HEAT

TO TANK

CIRCUT

I

PPESSSRE -

RREU SU

TO BURNER

SWITCH

BR AKER

E

GAGE

VALVVEMEO.44

VAL

E NO.

N

CLOSED

PRI

CAUTION: ENSURE PROPER

ENGAGEMENT OF QUICK

DISCONNECT COUPLINGS

Procedure

Not Fully

Item

Interval

Man

Item to be

Mission

No.

Hour

Checked/

Capable If:

Serviced

Pump Unit

(Cont)

Control Panel

DURING

7

CAUTION

Assembly

Do not operate pump dry or when

discharge pressure is below 60 psi.

If more time is needed to correct

fault, shut down.

Check that gages work and read correctly:

PRESSURE

VACUUM GAGE: 0-30 inches of mercury,

GAGE,

Water PRESSURE GAGE: 60-120 psi,

VACUUM

FUEL INDICATOR Gage: above empty

GAGE, FUEL

VOLTMETER: registers in green range

INDICATOR, or

LOW OIL PRESSURE LIGHT: is not illuminated

VOLTMETER is

not working or

LOW OIL

PRESSURE

LIGHT

illuminates.

0017 00-4