CHAPTER 4

REPAIR AND OVERHAUL INSTRUCTIONS

Section I. OVERHAUL AND REPLACEMENT STANDARDS

120. General

The following tables provide overhaul and replacement standards far the water distributor engine and

pump, defining maximum and minimum installation clearances, tolerances, wear limits, and nut and bolt torque

data.

121. Description

The power pumping unit is comprised of a four cylinder air cooled gasoline engine and a self-priming

centrifugal pump mounted on the engine crankcase.

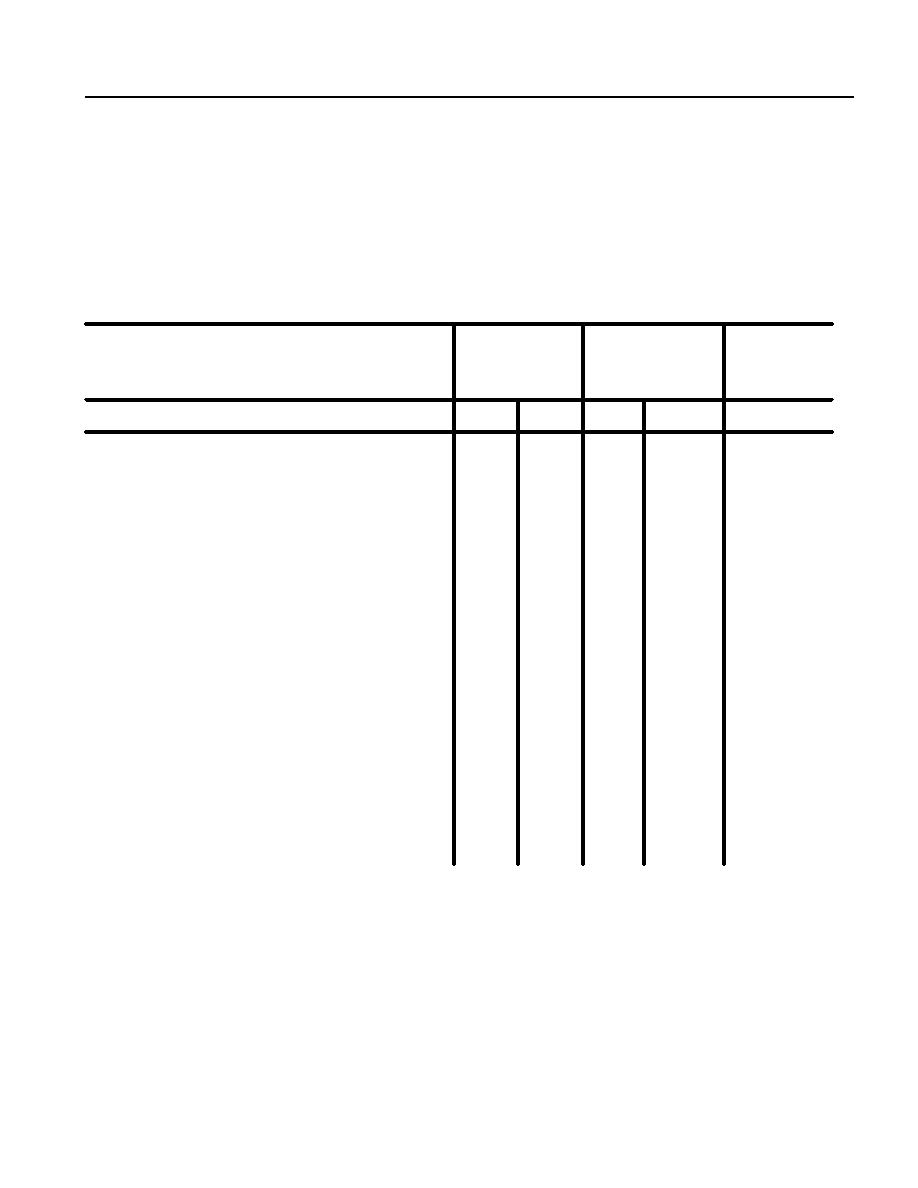

Table 2. Engine Repair and Replacement Standards

Manufacturer's

Maximum

Dimensions

Desired

Allowable

and tolerance

Clearance

Wear and

in inches

Clearance

Minimum

Maximum

Minimum Maximum

Camshaft:

Diameter of Journals:

No. 1 Journal..................................................................................

1.8725 1.8730

.........................................

0.0035

No. 2 Journal..................................................................................

1.2475 1.2480

.........................................

0.0035

Camshaft Bores in Crankcase:

Nominal dimension of inside diameter:

No. 1 Journal..................................................................................

1.875

1.876

.........................................

0.0035

No. 2 Journal..................................................................................

1.250

1.251

.........................................

0.0035

Clearance between camshaft journal

and crankcase bore.................................................................................................................. 0.002

0.0035

Connecting Rod:

ID of Crankshaft End .....................................................................

1.9370 1.9375

ID of Installed Bushing (crankshaft end)........................................

1.8115 1.8125

Clearance between bushing and crankshaft..........................................................................

0.0019

0.0025

0.003

Side clearance between bushing and

crankshaft ................................................................................................................................ 0.004

0.011

0.016

Maximum out of round of bushing

(crankshaft end).................................................................................................................................................................

0.0005

ID of Piston End.............................................................................

0.9125 0.9130

ID of Installed Bushing (Piston End)..............................................

0.8594 0.8597

.........................................

0.001

Interference OD of bushing to ID of rod................................................................................... 0.0025

0.0055

Clearance between piston pin and bushing............................................................................. 0.0005

.

0.001

0.001

Allowable twist of connecting rod

measured 3 inches from end............................................................................... 0.002

Crankshaft:

Nominal dimension of main bearing:

Journal diameters ....................................................................

1.8100 1.8105

.........................................

0.002

End Play of Crankshaft Bearing.......................................................................................

0.002

0.004

Adjustable

Cylinders:

Nominal dimension of bore diameter..............................................

3.254

3.255

.........................................

0.005

AGO 6571A

69