TM 5-4610-233-13&P

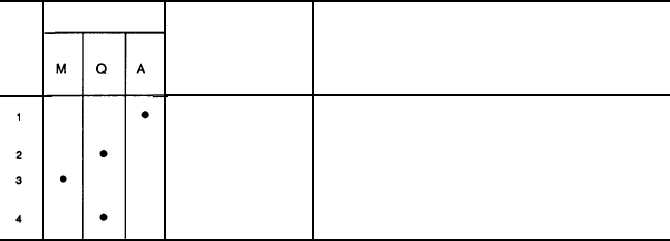

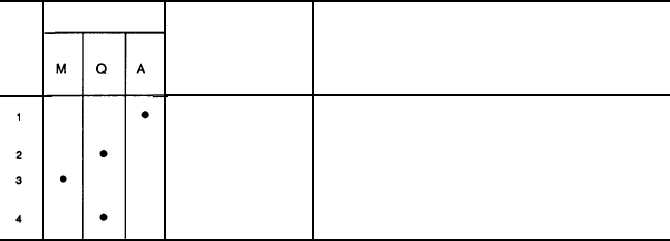

Item

no.

Table 4-1. Unit Preventive Maintenance Checks and Services (Interval) Schedule

M - Monthly

Q - Quarterly

A - Annually

Interval

Item to be

inspected

Solution feed pump

diaphragm

Flow controller

4-inch manifold

Frame

Procedures

lnspect for splitting, cracking, and dry rot.

Inspect for damaged threads,

Inspect for cracks, chipping, damaged gaskets, damaged bolts and

nuts, and damaged flanges.

Inspect for cracks, broken welds, and missing data plates.

Section IV. TROUBLESHOOTING

4-7. GENERAL. This manual cannot list all malfunctions that may occur, nor all tests of inspections and

corrective actions. If a malfunction is not listed or is not corrected by listed corrective actions, notify your

supervisor.

4-8. TROUBLESHOOTING TABLE. The troubleshooting table (table 4-2) lists the common malfunctions which

you may find during the operation or maintenance of the hypochlorination unit or its components. You should

perform the tests/inspections and corrective actions in the order listed.

Table 4-2. Unit Troubleshooting

Malfunction

Test or inspection

Corrective action

1. SOLUTION FEED PUMP AIRLOCKED AT STARTUP

WARNING

Hypochlorite solution is toxic to skin and eyes. Wear skin

and eye protection to prevent personal injury.

Step 1. Check that check valves in solution feed pump suction hose and pump discharge hose are

good.

Repair check valves. Refer to paragraph 4-24.

4-3