TM 55-1930-209-14&P-1

NOT TO SCALE

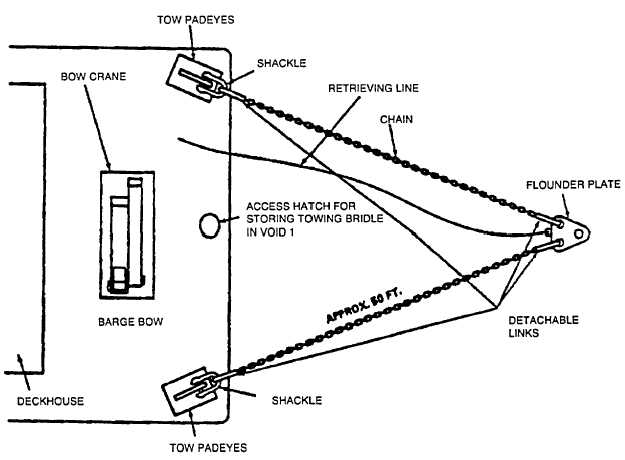

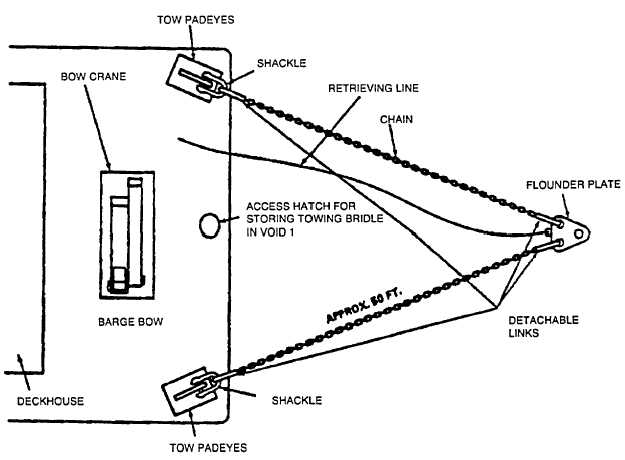

Figure 16-2. Towing Equipment Installation

(1)

Using bow crane to hold flounder plate at eye level, inspect plate and attaching hardware for

twists, cracks, or other damage or weaknesses.

(2)

Lift towing bridle and inspect chains for cracks, twisted links, or other damage or weaknesses.

(3)

Inspect shackles for cracks or twisted or bent metal.

h.

If towing bridle is damaged or shows signs of possible weakness, red tag bridle to show that it is not

serviceable. Notify intermediate support maintenance unit of requirement for repairing towing bridle.

i.

Inspect towpads for cracks, excessive wear, broken welds, and twisted or bent metal. If either towpad

shows signs of damage or possible weakness, notify intermediate support maintenance unit of

requirement for repairing a towpad.

j.

Using bow crane, suspend towing bridle over void 1 towing bridle access hatch and apply multipurpose,

water-resistant grease (MIL-G-24139A) to shackles, chains, and plate.

k.

Lower towing bridle into void 1 storage area.

I.

Make sure long dimension of flounder plate is vertical so plate will clear access hatch. Lower flounder

plate into storage area. Unhook bow crane cable hook.

m.

Secure towing bridle access hatch.

n.

Place bow crane in stowed position by following procedures in Chapter 10.

16-4