TM 55-1930-20-14& P-14

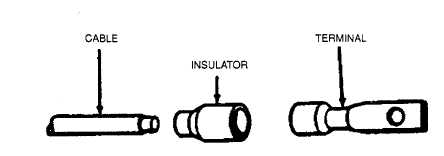

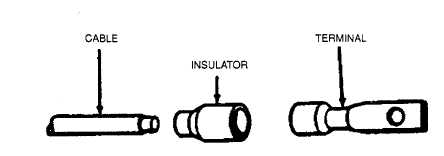

(1) Strip cable insulation equal to depth of terminal well.

(2) Slide insulator (if used) over cable.

(3) Insert cable into terminal well and crimp.

(4) Slide insulator (if used) over crimped end of terminal.

Figure 2-6. Replacement of Crimped Terminals

NOTE

Due to this vessel's mission and crew capabilities, maintenance normally

assigned to organizational level or higher echelons may be assigned to

the crew by the Bargemaster.

2-19.2 Lubrication. Use lubricants specified on page 4 of 4 in the W. W. Patterson service manual in Appendix B to

lubricate anchor winch. Lubricate anchor winches and fairleaders as instructed in the preventive maintenance checks

and services in Appendix C. Change lubricants as instructed in the periodic checks and services.

2-19.3 Repair or replacement of anchor winch components

WARNING

Shut down anchor winches before attempting maintenance. Be sure to

open (OFF) circuit breaker P10 on switchboard to shut down anchor

winches 1 and 2, circuit breaker P11 on switchboard to shut down anchor

winches 3 and 4, and circuit breaker 11 P13 on power panel 3 to shut

down heaters in anchor winches.

2-19.3.1

Anchor winch electric brake repair and replacement. The electric brake is a Stearns, 105 lb-ft. 87,000

series self-adjusting disc brake with an internal space heater.

2-19.3.1.1

Cleaning and inspection

a.

Make sure anchor winch is electrically dead by opening (OF F) switchboard circuit breakers P10 or P11 and

power panel 3 circuit breaker 11P13. Redtag circuit breaker with: 'WARNING -DO NOT ACTIVATE. REPAIRS

BEING MADE.”

b.

Visually inspect exterior for damage, corrosion or chipped paint. Remove corrosion and touch up paint according

to TB 43-0144. Do not paint threads or labels.

c.

Wipe clean exterior of electric brake and motor with clean rag.

WARNING

Always wear a filtered mask or respirator while removing dust from the

inside of the brake while servicing or adjusting brake. Brake friction discs

contain asbestos which is dangerous to your health if inhaled.

d.

Upon opening electric brake, vacuum clean or use a soft electrician's brush to remove dust. When brushing,

avoid causing the dust to become airborne. Collect the dust in container which can be sealed.

2-17