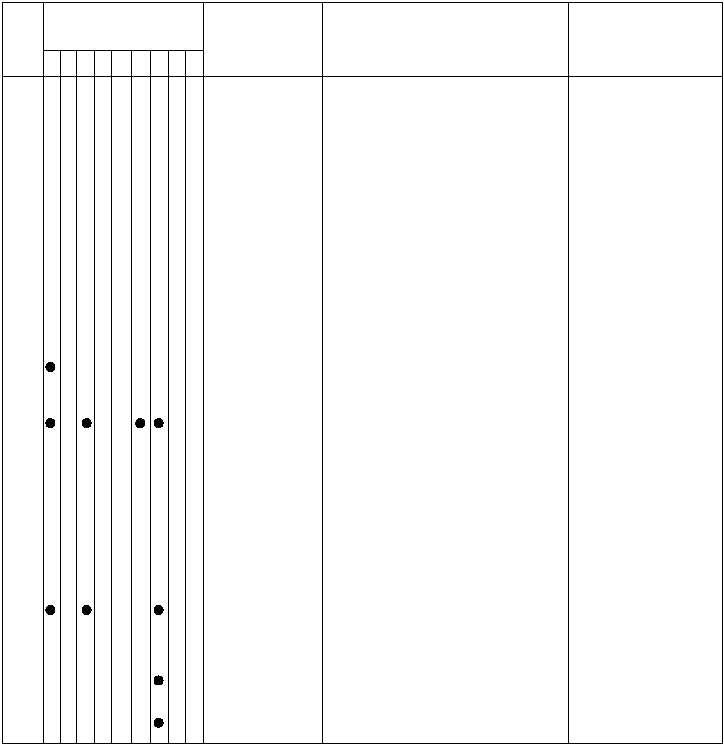

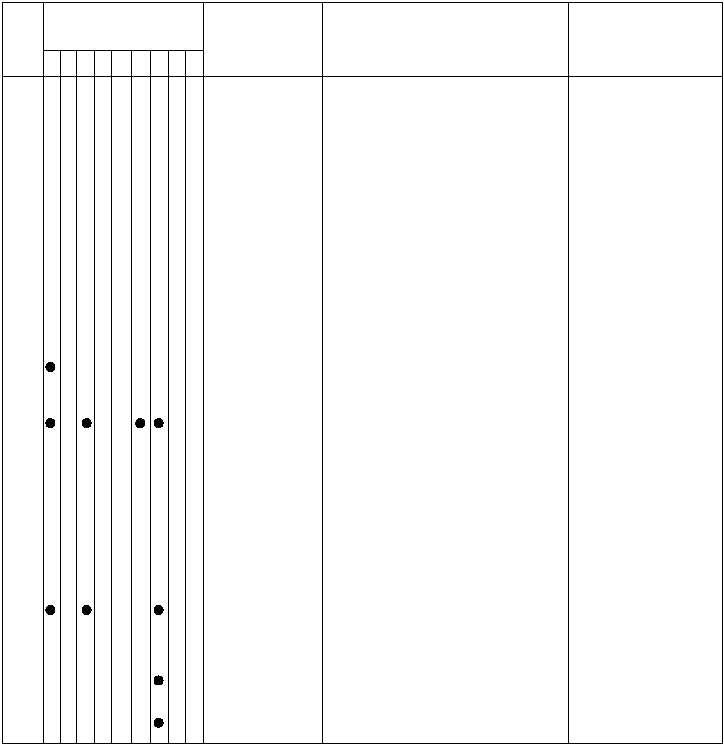

TM 55-1930-209-14&P-19

Table 2-4. Preventive Maintenance Checks and Services for Handling Equipment (Continued)

B -

Before

D -

Daily

Q - Quarterly

D -

During

W -

Weekly

S - Semiannually

A -

After

M -

Monthly

A - Annually

INTERVAL

ITEM

PROCEDURES

EQUIPMENT

ITEM

TO BE

CHECK FOR AND HAVE

IS NOT READY/

NO.

INSPECTED

REPAIRED OR ADJUSTED

AVAILABLE IF

B D A D W M Q S A

AS NECESSARY

CAUTIONS

Always center hoist over the load before lift-

ing. This prevents side loading and uneven

tension on load-bearing components. Avoid

swinging load when transporting it.

Bent hooks indicate component has been

overloaded. Replace hook and inspect all

other load-bearing parts for damage.

NOTE

When repairing or replacing parts, use parts

of original construction. All materials used

should be according to void 4 trolley hoist

drawing and appropriate repair manual.

a. Check barge maintenance log for dis-

crepancies that would prevent using trol-

ley hoist.

b. Check hoist for damaged hook or chains.

Hooks and/or

Check that hoist and attaching hardware

chain damaged.

are secure, clean, and properly lubri-

cated.

WARNING

Corrosive prevention compounds are

flammable and slightly toxic. Avoid contact-

ing skin and eyes as well as breathing

vapors. Skin, eye, and breathing protection

is required.

c. Remove rust and corrosion from hoist

and components. Touch up paint in

accordance with TB 43-0144 as neces-

sary. Do not paint threads or labels.

d. Visually check chain drive wheels for

Chain drive wheels

excessive wear. Repair as necessary.

are excessively worn.

e. Check braking and locking device for

Brakes and locking

proper operation. Repair as necessary.

device inoperable.

13-12