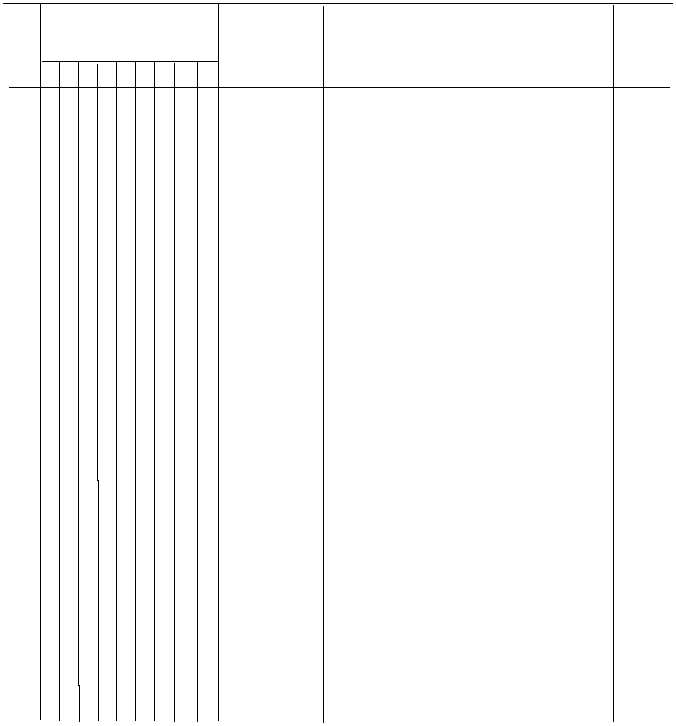

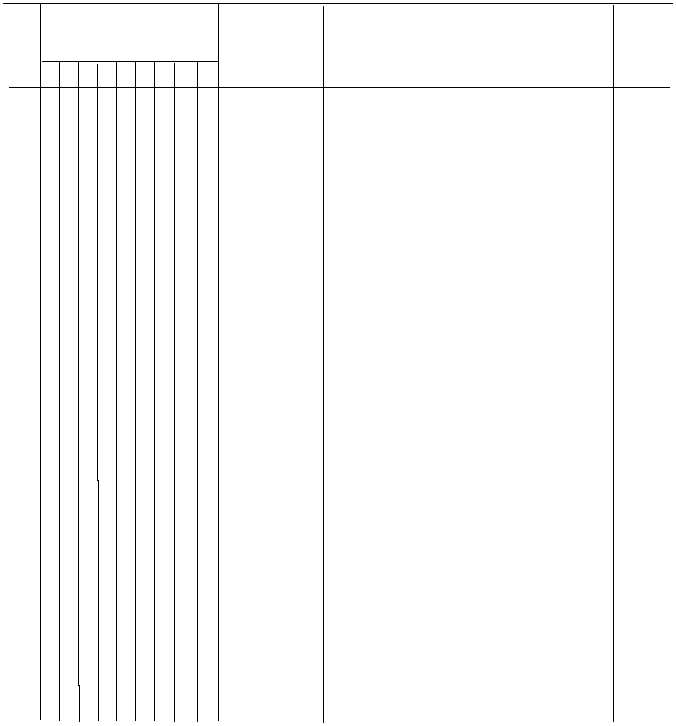

TM 55-1930-209-14&P-3

Table B-1. Preventive Maintenance Checks and Services for ROWPU System (Continued)

B-Before

D-Daily

Q-Quarterly

D-During

W-Weekly

S-Semiannually

A-After

M-Monthly

A-Annually

ITEM

PROCEDURES

INTERVAL

TO BE

CHECK FOR AND HAVE

EQUIPMENT

ITEM

INSPECTED

REPAIRED OR ADJUSTED

IS NOT READY/

NO.

AS NECESSARY

AVAILABLE IF:

B D

A D W M Q

S

A

3) Close valve RO14 on hose connected

to small threaded drum bunghole.

4) Disconnect hose containing valve

R014.

5) Tip drum from vertical position and

remove using drum lifter and bridge

crane with 2-ton hoist.

NOTE

Membrane cleaning agent drum is normally

painted black.

6) Use drum lifter and bridge crane with

2-ton hoist to position drum to stand

so large bunghole is on bottom and

small bunghole is on top when drum is

tipped into place.

7) Connect hose containing valve RO14

to small threaded drum bunghole.

8) Connect hose containing valve R013

to large threaded drum bunghole.

4

Media Filters

a. Check each media filter unit for damage

and leaks. Check vent valve for proper

operation. Replace vent valve as

required. Unscrew existing air vent on

top of media tank and install new vent

(P/N 51896-1).

b. Backwash and flush media filters when

Pressure in P1

pressure difference between seawater

and P2 exceeds

pump discharge pressure gauge P1 and

35 psi.

media filter output gauge P2 exceeds 35

psi, when MEDIA FILTER LIGHT OK light

goes out, or when water sample taken

from cartridge filter assembly drain valve

R08 is dirty.

c. If HP pump diesel engine is operating:

1) Position valve RO15 from product

water flow to overboard flow.

B-9