TM 10-4610-232-12

3-32. REPAIR WASTE WATER HOSES AND ADAPTERS. This task covers repair of hoses by replacement of

gaskets as described in paragraph 3-8.

3-33. SERVICE AIR COMPRESSOR ASSEMBLY. This task covers:

a. Inspection.

b. Service.

INITIAL SETUP.

Materials/Parts:

General Safety Instructions:

Filter, Inlet (Appx E, Sec II, Item 39)

Lubricating Oil (Appx E, Sec II, Item 52)

WARNING

Equipment Condition:

Do not work on the inlet filter or check air compres-

COMPRESSOR OFF/ON switch (14, Figure 2-4)

sor oil level when either the air compressor or high

is OFF.

pressure pump are running. Noise level inside high

COMPRESSOR ON green light (9) is not lit.

pressure pump assembly cover could cause deaf-

HIGH PRESSURE PUMP STOP switch (22) is

ness.

pressed.

HIGH PRESSURE PUMP ON (13) green light

is not lit.

INSPECTION.

a. Check condition of switches and green lights.

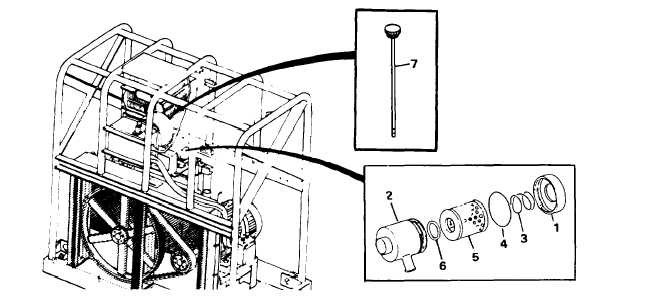

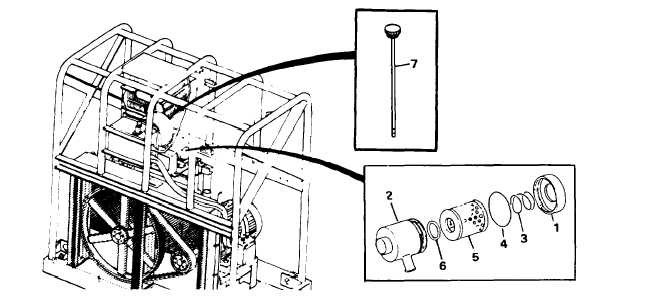

b. Unscrew the inlet filter cover (1, Figure 3-19) from housing (2).

c. Remove the spring (3), seal (4), filter element (5), and seal (6) from the housing (2).

d. Check condition of spring(3), and seals (4and6). If cut or damaged, request replacements from unit maintenance

and replace at next filter element replacement interval.

e. Check oil level dipstick (7). Oil should be between marks at bottom of dipstick.

Figure 3-19. Air Compressor

3-63