TM 10-4610-232-12

a.

b.

c.

d.

Add oil to obtain level near (but below) upper mark on dipstick.

Install new filter element (5).

If worn or damaged, replace spring (3) and seals (4 and 6), otherwise reinstall existing parts.

Install cover on housing, securely hand tighten.

3-34. SERVICE HIGH PRESSURE PUMP ASSEMBLY. This task covers:

a. Inspection.

b. Service.

Materials/Parts:

General Safety Instructions:

Lubricating Oil (Appx E, Sec II, Item 52)

WARNING

Equipment Condition:

COMPRESSOR OFF/ON switch (14, Figure 2-4)

Do not work on the high pressure pump assembly

is OFF.

when either the air compressor or high pressure

COMPRESSOR ON green light (9) is not lit.

pump are running. Noise level inside high pressure

HIGH PRESSURE PUMP STOP switch (22) is

pump assembly cover could cause deafness.

pressed.

HIGH PRESSURE PUMP ON (13) green light

is not lit.

INSPECTION.

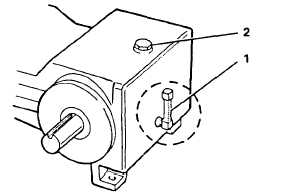

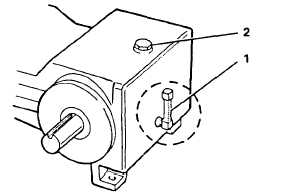

a. Check oil level in high pressure pump sight gage (1, Figure 3-20).

b. Level should be at least at mid-point on gage.

c. Check for water leaks.

d. Check for milky looking oil.

a.

b.

c.

Remove oil add plug (2).

Add oil at plug port until sight gage (1) gives mid level reading.

Replace plug (2).

Figure 3-20. High Pressure Pump Oil Level

3-64