TM 10-4610-232-34

f. Assemble cross heads (23), connecting rods (7), wrist pins (22), and setscrews (21).

g. Install connecting rod bolts (8) on connecting rods.

NOTE

Make sure that oil slots and oil pockets are facing upward.

h. Install cross head assemblies (19) into the same bores from which they were removed.

CAUTION

Be careful not to damage cylinder bores or crankshaft during installation.

i. Install sleeve bearings (8) on connecting rods (7). Push connecting rods and connecting rod bolts (9) all the way into

cylinders for ease in crankshaft installation.

j. Install gasket (14), shim (15), and bearing housing (12) (in that sequence) on pump case. Install bolts (10) and

tighten to 55 ft-lbs (75 Nm).

k. Carefully install the crankshaft (16) in the pump case through the side bearing bore.

l. Carefully put the crankshaft in position against the bearing housing and install gasket (14), shim (15) and bearing

housing (13).

m. Install bolts (11) and tighten to 55 ft-lbs. (75 Nm). Spin the crankshaft to seat the bearings.

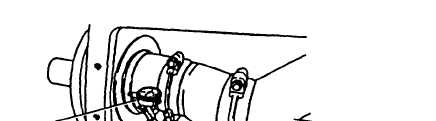

n. Measure the crankshaft end play as shown in Figure 3-7.

(1) Place a dial indicator on the pump case (1, Figure 3-7) and against crankshaft (2).

(2) Move the crankshaft fully to one side of pump case.

(3) Set the dial indicator (3) to zero.

(4) Push the crankshaft fully against bearings at opposite side of case.

(5) The reading on the dial indicator is the crankshaft end play. End play must be 0.002 to 0.005 in. (0.05 to 0.12

mm).

(6) Add or remove shims (15, Figure 3-6) as necessary to obtain correct crankshaft end play. Tighten bolts (10 and

11) to 55 ft-lbs (75 Nm).

o. Carefully push cross head assemblies (19) toward crankshaft (16) and position connecting rods (7) over

crankshaft.

p. Install sleeve bearings (8) in caps (6).

q. Install caps (6) on crankshaft and install nuts (5) on connecting rod bolts (9). Tighten connecting rod bolts (9) to

65-70 ft-lbs (88-95 Nm).

r. Install gasket (4) and rear cover (3) on pump case. Tighten sixteen capscrews (2) to 15-25 ft-lbs (20-34 Nm).

s. Install oil level sight gage (1).

Figure 3-7. Crankshaft End-Play

3-18