TM 10-4610-240-10

TM 08580C-10/1

T.O. 40W4-13-21

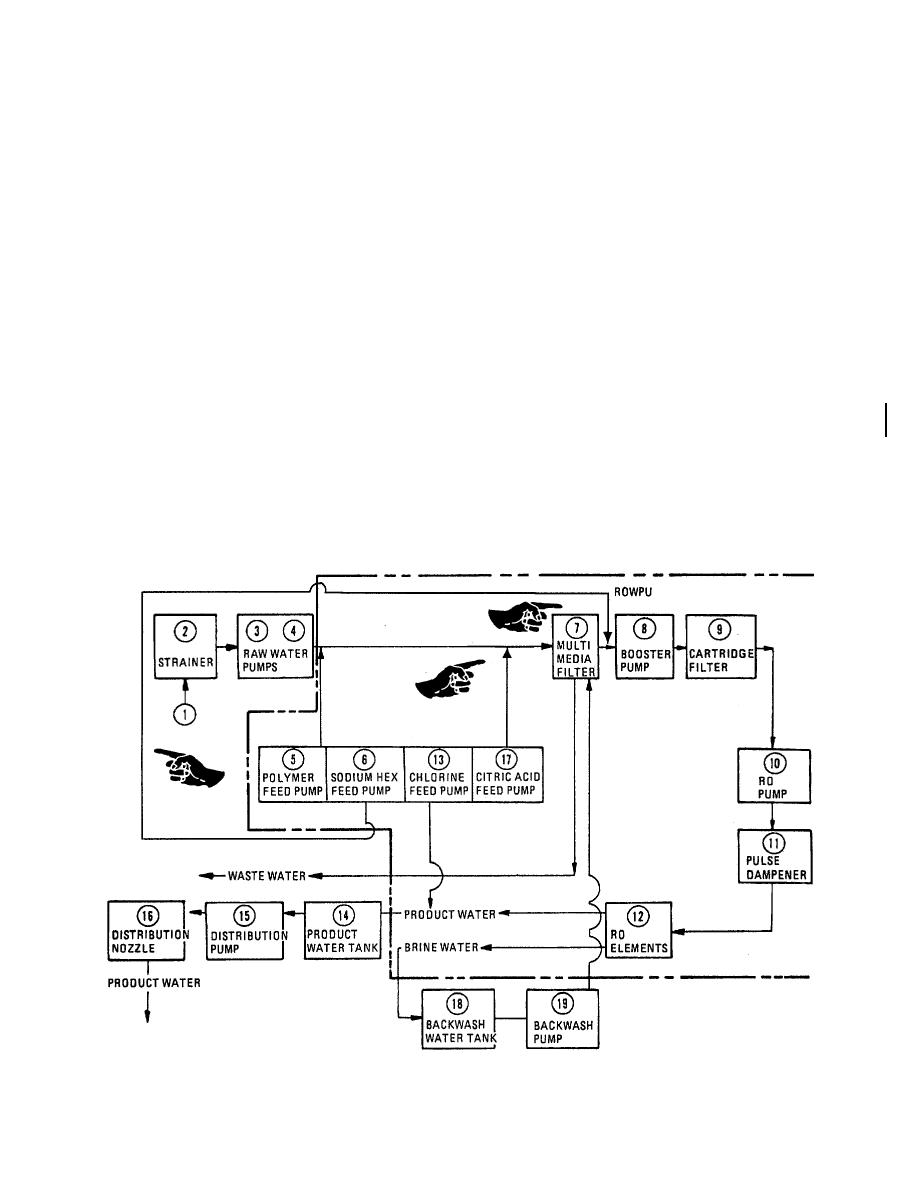

1-10. REVERSE OSMOSIS (R.O.) PROCESS - continued.

CHLORINE FEED PUMP (13). Adds chlorine to product water to reduce bacteria to an acceptable level to make water

in tanks potable. Chlorine is injected after the reverse osmosis takes place.

PRODUCT WATER TANKS (14). Storage containers for product (potable) water.

DISTRIBUTION PUMP (15). Pumps potable water from product water tank into the water carrying vehicle or container.

DISTRIBUTION NOZZLE (16). Used for filling user's container with potable water coming from product water tanks by

way of the distribution pump.

CITRIC ACID FEED PUMP (17). Adds diluted citric acid to filtered water to maintain the optimal pH for the R.O.

process; aids in preventing scale buildup inside the R.O. membranes. To prevent coagulation at the R.O. elements

make sure that the Citric Acid is fed prior to the item () .

BACKWASH WATER TANK (18). Stores brine water used for backwashing the multimedia filter and for cleaning the

R.O. elements.

BACKWASH PUMP (19). Pumps brine water from the brine tank, through the backwash strainer, and into the

multimedia filter to flush accumulated solids out of media.

FIGURE 1-15. WATER PROCESSING BLOCK DIAGRAM

Change 2 1-19/(1-20 blank)