TM 10-4610-246-13

4.21

MAINTENANCE OF PUMPER ASSEMBLY - (Cont)

NOTE

Threaded stud may stay in either diaphragm and

must not be discarded.

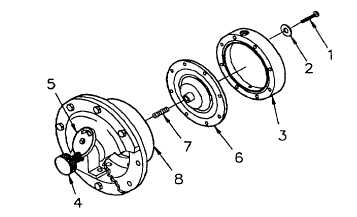

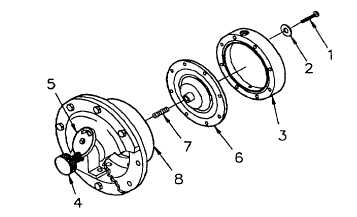

(c) Unscrew chemical side diaphragm

(6) and remove.

Protect threads when removing stud.

(d) Unscrew stud (7).

Figure 4-12. Pumphead

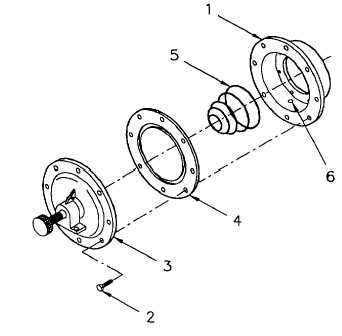

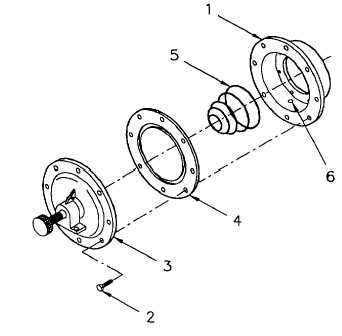

(2) Remove water side diaphragm.

(a) Turn stroke adjusting knob (4) CCW

until dial scale (5) reads 10.

(b) Place small end of cylinder (1) face

down on workbench.

NOTE

Put a realignment mark on cylinder flange.

(c) Remove all but two capscrews (2)

which will be opposite each other.

Maintain pressure on the water side diaphragm

flange when removing it during maintenance. The

water side diaphragm is under spring pressure.

Uncontrolled release may cause injury to personnel.

(d) Push flange (3) down to relieve spring pressure and remove remaining two capscrews (2) slowly.

(e) Slowly lift flange (3) off, releasing spring

pressure.

(f) Remove water side diaphragm (4).

4-21

Figure 4-13. Water Side Diaphragm