ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0050 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

DIESEL ENGINE AND FUEL TANK ASSEMBLY

NOTE

The metal shim under the fuel injection pump base plate is required for proper

operation. Be sure the shim is in place when replacing the fuel injection pump.

5. Verify that the ID number stamped on the left side of the new pump's base plate matches the ID

number (48R) on the old pump.

NOTE

Do NOT install the new pump if the ID number doesn't match. Fuel injection

pumps are not interchangeable between engine models. Be sure to properly orient

the pump when installing it.

6. Install the shim, the new pump and the inspection window cover and gasket. Fasten them in

place using the three nuts. Torque the nuts to 95-113 in.-lbs.

7. Reattach the fuel injection pipe to the pump and fuel injection valve.

8. Reinstall the fuel supply hose assembly using the clamp.

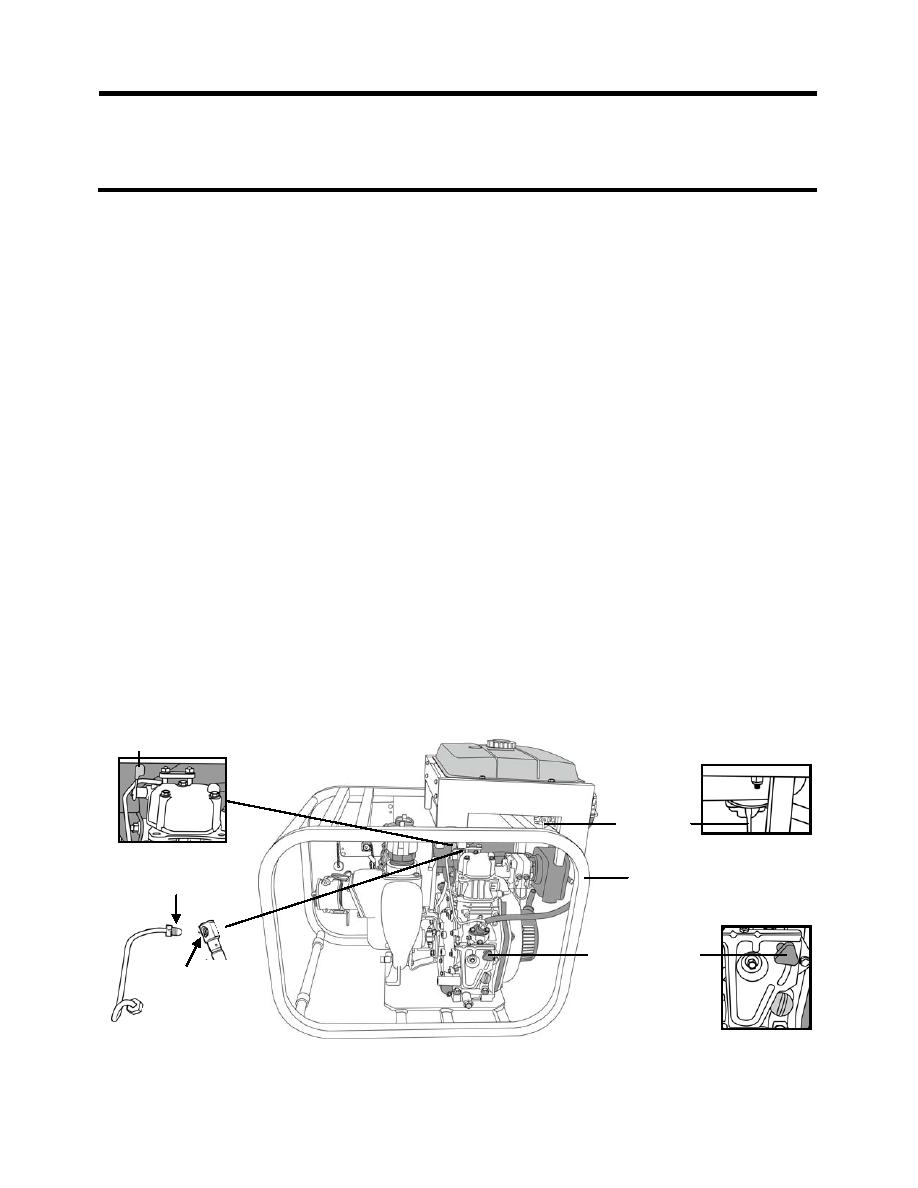

After replacing the fuel injection pump, bleed the fuel system of trapped air as follows (see Figure 12):

1. Install the fuel tank assembly on the pump skid and connect the fuel supply and return line quick

disconnect couplings.

2. If necessary, pour a small amount of fuel into the tank.

3. Open the fuel cock.

4. Place the engine speed control knob at the Start position.

5. Disconnect the fuel injection pipe from the fuel injection valve.

6. Push the engine decompression lever down (non-compression position) and hold it there.

7. Place a rag in front of the disconnected end of the fuel injection pipe.

8. Pull the recoil starter. Stop when you see fuel spraying out the fuel injection pipe.

9. Reconnect the fuel injection pipe to the fuel injection valve.

DECOMPRESSION LEVER

FUEL COCK

(OPEN)

FUEL INJECTION

DIESEL ENGINE-DRIVEN

PIPE

PUMP SKID

SPEED CONTROL

KNOB (IN START

FUEL INJECTION

POSITION)

VALVE

Figure 12. Diesel Engine Fuel System Bleed.

0050 00-13