ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0053 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

HIGH PRESSURE PUMPS

3) Clean and rinse the cam thoroughly with fresh water before reinstalling.

4) Inspect the keyway and remove any dirt, sharp edges, or nicks that could

damage the shaft seal at installation.

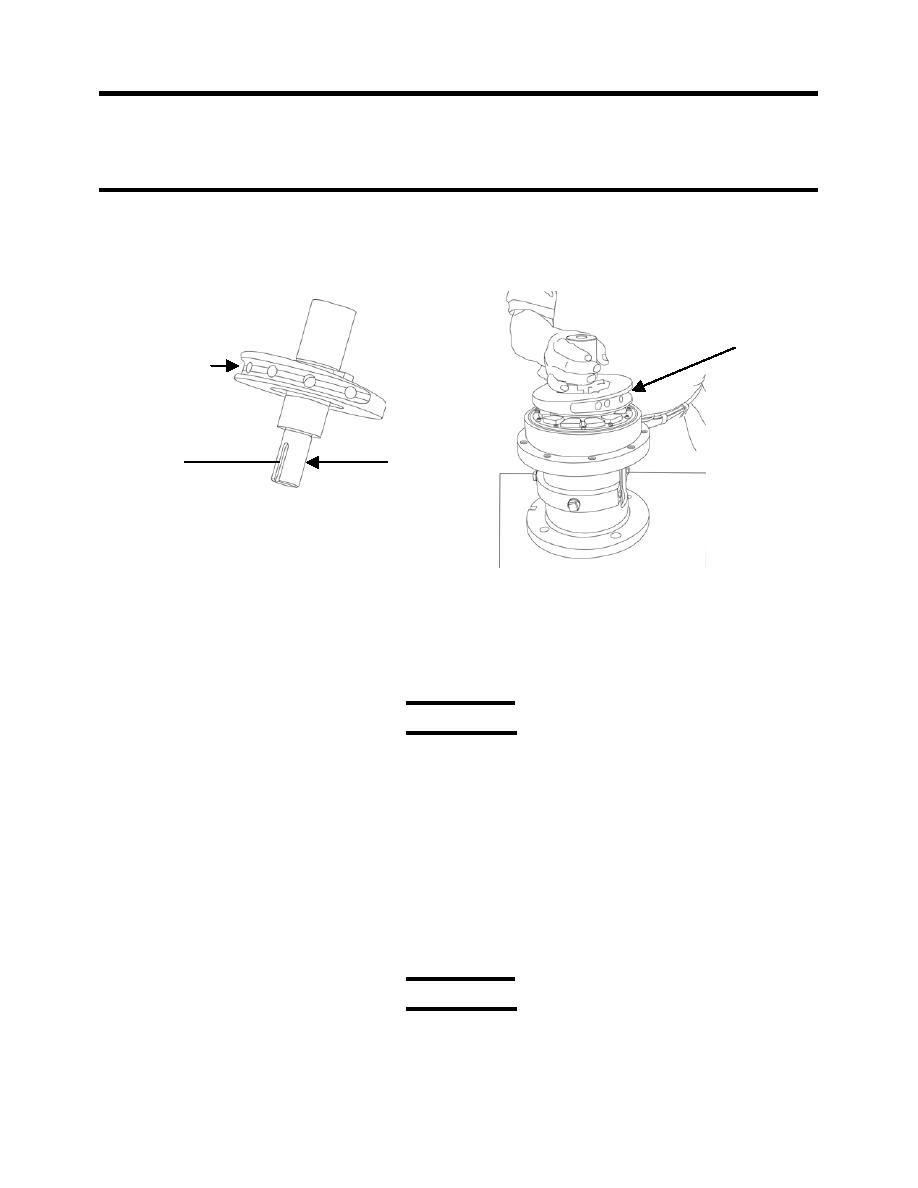

HPP CAM

CAM

KEYWAY

SEAL SURFACE

Figure 20. HPP Cam Inspection and Installation.

g. Install the cam as follows (see Figure 20):

1) Carefully rinse the cam with clean fresh water.

2) Apply glycerin to the cam seal surface.

CAUTION

Care is required when installing the cam to prevent damage to the shaft seal. Do

not pierce or damage the shaft seal in any way. Make sure the key way faces the

opening in the flange when the cam is installed. Failure to observe this caution

may result in damage to the shaft seal causing it to leak during operation.

3) Slide the camshaft through the bearing plate and the shaft seal.

6. Perform the 1000-Hour PMCS procedures. Refer to SERVICE and 1000-Hour High Pressure

Pump PMCS.

7. Install the high-pressure pump onto the motor. Refer to High Pressure Pump or Motor

Replacement.

8. Install the high-pressure pump assembly onto the TWPS. Refer to High Pressure Pump

Assembly Replacement.

CAUTION

Failure to follow the break-in procedure listed below may cause premature failure

of the cam, thrust cluster, or tilt pad bearings or it may result in excessive power

consumption by the pump.

0053 00-18