ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0053 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

HIGH PRESSURE PUMPS

e. Lubricate the bearing bore with a small amount of clean, fresh water before installing the

bearing.

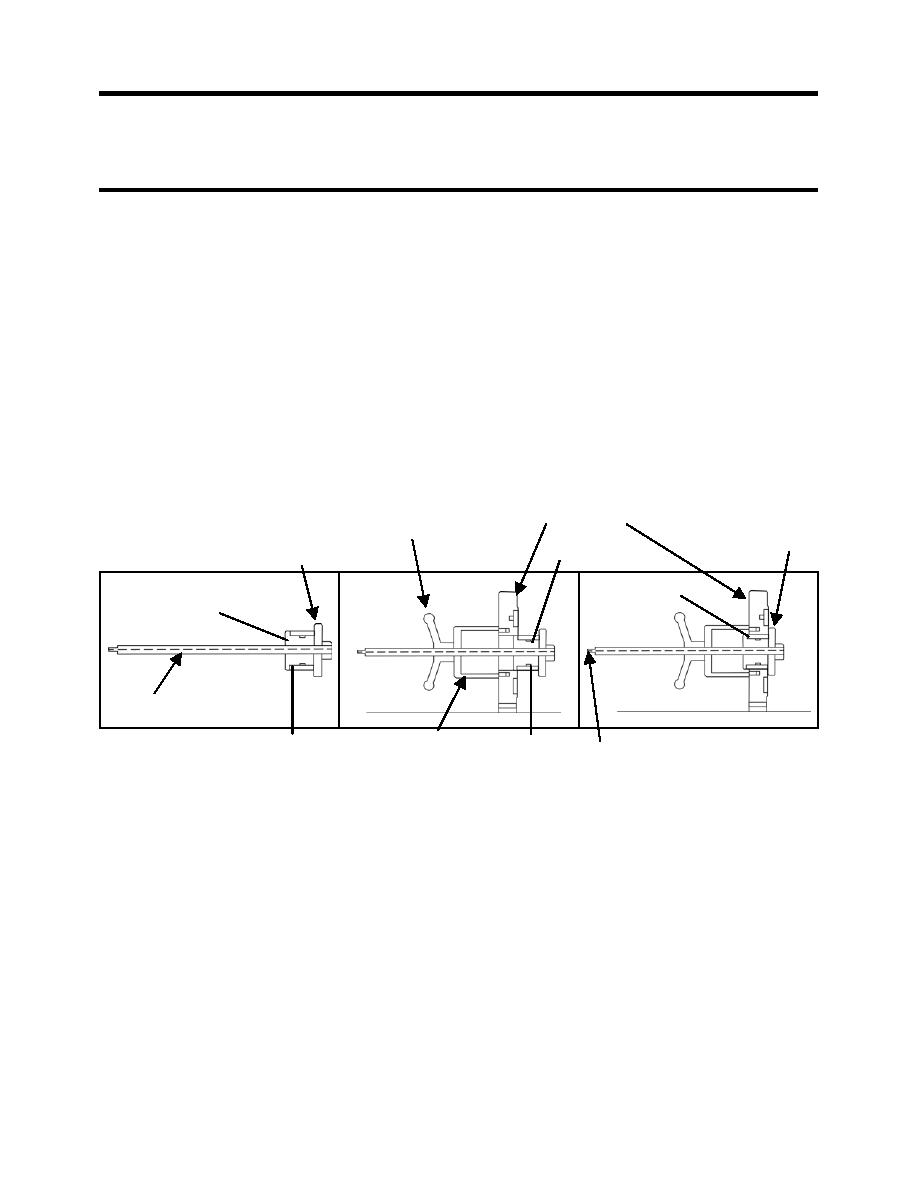

f. Insert the threaded end of the tension rod through the cam side of the bearing plate.

NOTE

The shoulder of the pilot plug enters the bearing bore before the bearing makes

contact with the bearing plate.

g. Place the adapter can over the tension rod on the opposite side of the part. Slide the

adapter can down the tension rod until it rests on the bearing housing.

h. Screw the speedball handle onto the tension rod until the speedball handle contacts the

adapter can.

i. Continue to rotate the speedball handle clockwise until the reaction plate stops against

the cam side of the bearing plate.

j. Remove the tool from the new bearing.

BEARING PLATE, CAM SIDE

SPEED BALL HANDLE

REACTION PLATE

PILOT PLUG

REACTION PLATE

NEW BEARING

PILOT PLUG

TENSION ROD

WRENCH FLATS

NEW BEARING

ADAPTER CAN

NEW BEARING

Figure 25. Bearing Plate Bearing Installation.

5. Carefully clean and rinse all components before reinstalling in the pump.

6. Install the new shaft seal assembly onto the bearing plate using the allen head screws (see

Figure 21). Tighten the screws evenly in an alternating cross pattern. Torque to 60 in.-lbs.

7. Set the bearing plate onto the mounting flange so that the shaft seal assembly fits into the

opening at the top of the mounting flange (see Figure 21).

8. Install the bearing plate on the mounting flange (see Figure 26).

NOTE

Make sure that the counter bore hole or flat side of the thrust bearing engages the

alignment pin (protruding from the groove in the plate). The thrust bearing should

lie flat against the bottom of the groove in the bearing plate.

9. Install a clean thrust bearing.

0053 00-23