ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0058 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

PRODUCT WATER DISTRIBUTION SYSTEM

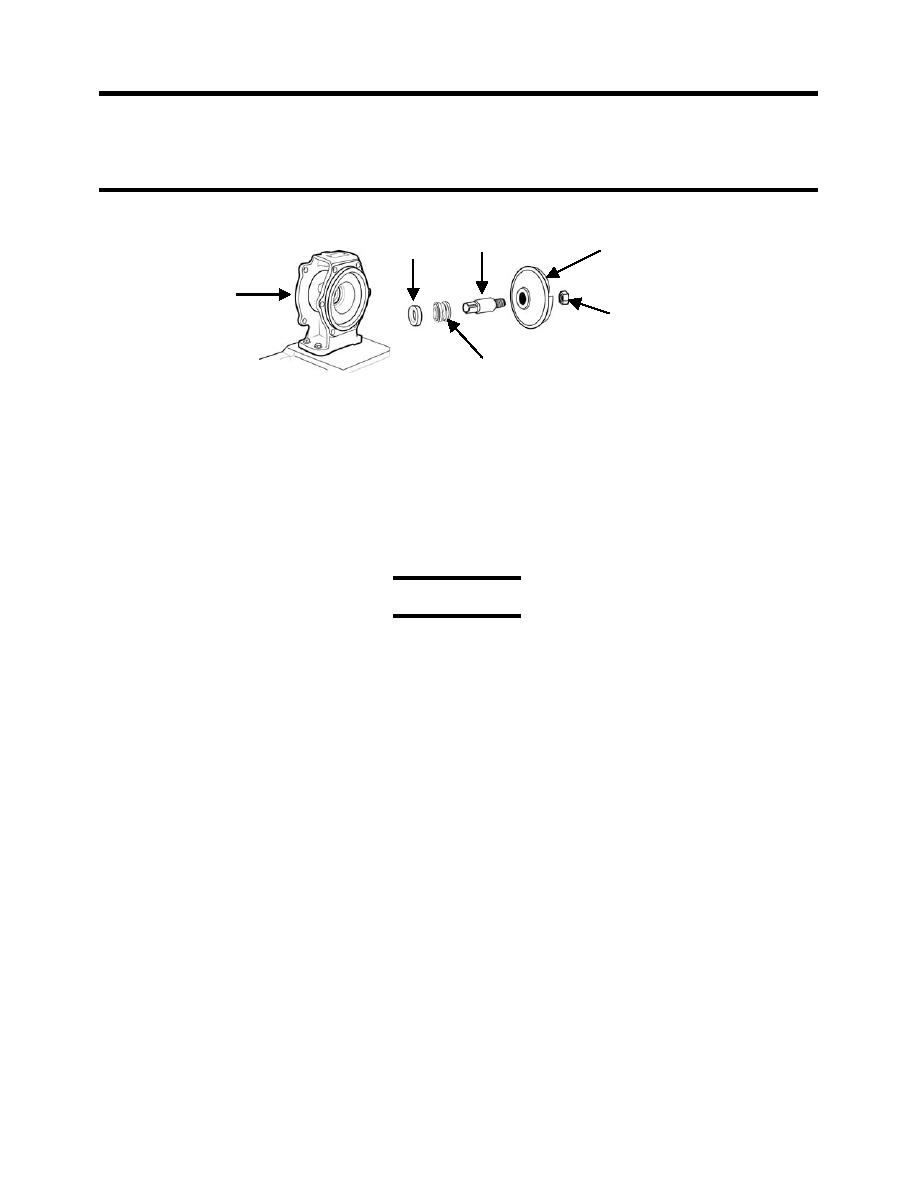

DRIVE SLEEVE

IMPELLER

SEAL SEAT

ADAPTER

IMPELLER LOCK NUT

SEAL ASSEMBLY

Figure 5. Drive Sleeve, Impeller, and Seal Assembly.

2. Install the new motor as follows:

a. If necessary, polish the new motor's drive shaft with fine abrasive cloth to remove any

rust or corrosion.

b. Attach the new motor to the adapter using the four cap screws and four lock washers.

c. Disconnect the motor cable from the old motor and attach it to the new motor. Refer to

REPLACE and P-7 Pump Motor Cable.

d. Lubricate the motor drive shaft and the inside diameter of the drive sleeve with corrosion

preventive compound.

CAUTION

Improper assembly can result in damage to the drive sleeve and the motor drive

shaft. Do NOT place a key between the drive shaft and the sleeve. Do NOT force

the drive sleeve onto the shaft. Failure to observe this caution can make impeller

clearance adjustments and the future removal of the drive sleeve difficult, and may

result in damage to the drive sleeve and/or the motor drive shaft.

e. Slide the drive sleeve and impeller assembly onto the drive shaft.

NOTE

If the sleeve does not easily slide onto the shaft, it may be necessary to remove

burrs from the shaft.

f. Install the coupling clamp assembly but do not tighten it.

g. Place a new housing gasket between the adapter and the pump housing.

h. Fit the pump onto the adapter and thread a nut on two opposing threaded studs to secure

the pump to the adapter. Tighten the two nuts.

3. Set the gap between the impeller and the pump wear plate as follows (see Figure 6):

a. Remove the four cap screws and 4 lock washers that secure the outlet flange to the

pump housing.

b. Carefully remove the pump flange to avoid damaging the gasket between the flange and

the pump housing.

c. If the gasket is damaged, replace it.

d. Look through the outlet into the pump. Turn the impeller drive sleeve and impeller by

hand until you see the impeller near the wear plate.

e. Insert a 0.015 inch feeler gauge between the impeller and wear plate. Move the

impeller forward or backward as needed to provide a gap of 0.015 to 0.017-inch.

0058 00-9