ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0066 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

GENERAL MAINTENANCE

5. Install the new butterfly valve assembly onto the actuator as follows:

a. Make sure the new valve is in the same normal position as the valve it is replacing.

1) The valve is either normally open (NO) or normally closed (NC).

2) A new valve can be moved to its proper starting position by securing the valve

body and using a wrench on the valve stem to turn the valve.

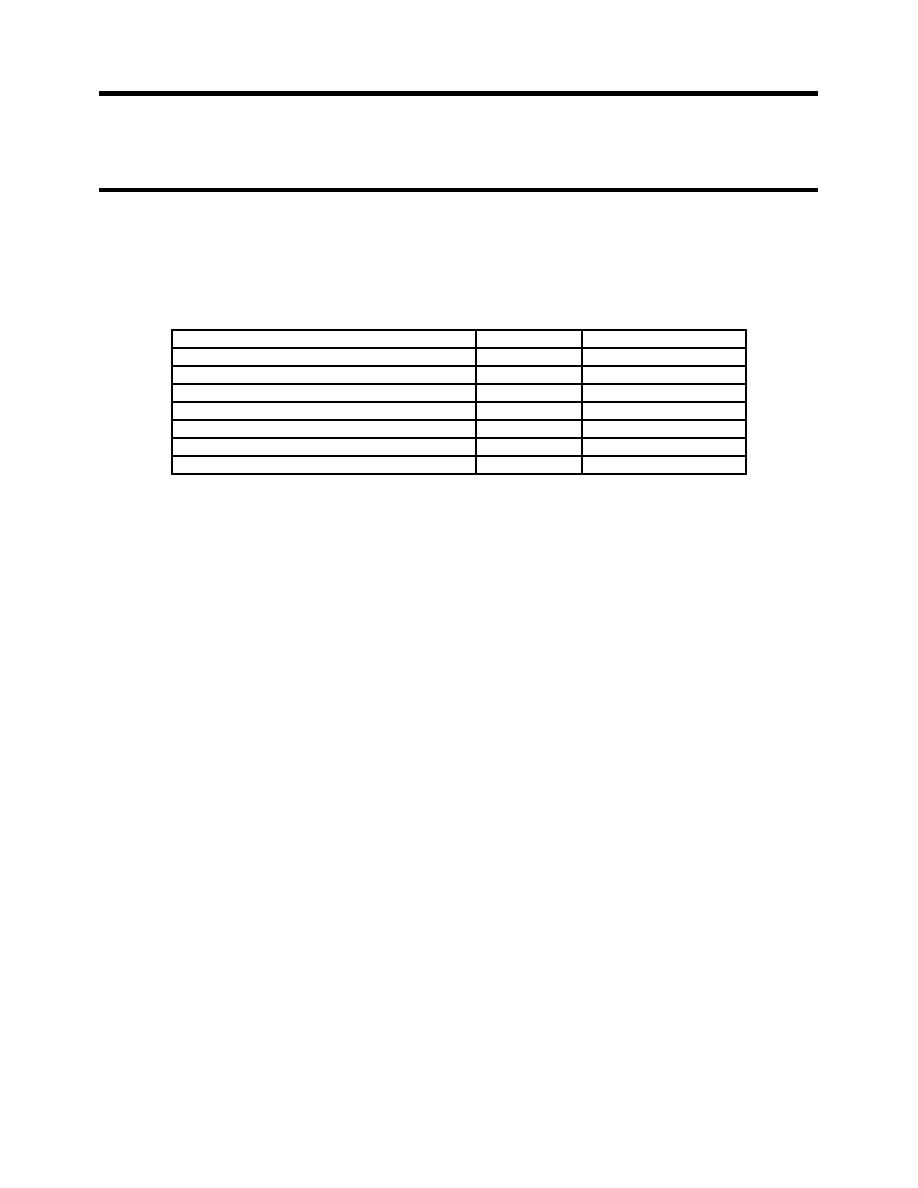

3) The table below lists each of the automatic valves and its normal position.

VALVE

VALVE SIZE

NORMAL POSITION

V-111 Main Feed Valve

3-in.

NO

V-112 Upper Feed Valve

2-in.

NO

V-113 Lower Feed Valve

3-in.

NC

V-201 Upper Filtrate Outlet Valve

2-in.

NO

V-202 Filtrate Flow Control Valve

2-in.

NO

V-401 Shell Backwash Upper Outlet Valve

3-in.

NC

V-402 Shell Backwash Lower Outlet Valve

2-in.

NC

b. Clean the actuator with clean, lint-free rags and inspect for corrosion, nicks and damage.

c. Apply sealing compound to the threads of the swivel joint adapter and thread the adapter

into the actuator.

d. For MF Lower Feed Inlet Valve V-113, see the Limit Stop Replacement procedures to

ensure proper limit stop installation.

e. If the shaft adapter and adapter sleeve fell out of or were removed from the actuator,

insert the shaft adapter into the actuator drive bore. Set the key of the shaft adapter into

the actuator bore keyway so that when the valve is assembled onto the actuator, the

valve body will be aligned with the actuator as shown in Figure 7.

f. Insert the shaft adapter sleeve into the shaft adapter.

g. Make sure a valve stem bushing is inserted over the new valve stem and into the opening

between the valve stem and valve body.

h. Insert the valve stem into the shaft adapter / adapter sleeve.

i. Make sure the valve body is aligned with the actuator as shown in Figure 7. If it is not,

remove the valve and the shaft adapter / adapter sleeve. Reinsert the shaft adapter into

the actuator bore with the adapter key fitted into the other keyway in the bore. Then

insert the shaft adapter sleeve and the valve stem.

j. Secure the actuator to the new valve with the 4 lock washers and cap screws.

6. Install the butterfly valve assembly onto the TWPS as follows:

a. Clean the pipe flanges with clean lint-free rags and inspect for nicks and any other

damage that may cause the flange to leak.

NOTE

Install the butterfly valve and actuator in the same position as the valve/actuator

assembly that was removed.

b. Separate the pipe flanges, insert the valve and secure the valve to the pipe flanges only

snug tight using the four bolts, eight washers, and four nuts that were removed earlier.

c. Make sure that the valve is centered between the flanges then tighten the nuts and bolts

in a crisscross pattern.

d. Push the air hose into the swivel joint adapter.

e. Check the new butterfly valve for leaks and proper operation.

0066 00-10