TM 3-4230-237-10

0016 00

OPERATOR'S PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS) - Continued

Table 1. Before Operation PMCS for M12A1 DED Decontaminating Apparatus - Continued.

7

9

8

6

Procedure

Not Fully

Item

Interval

Man

Item to be

Mission

No.

Hour

Checked/

Capable If:

Serviced

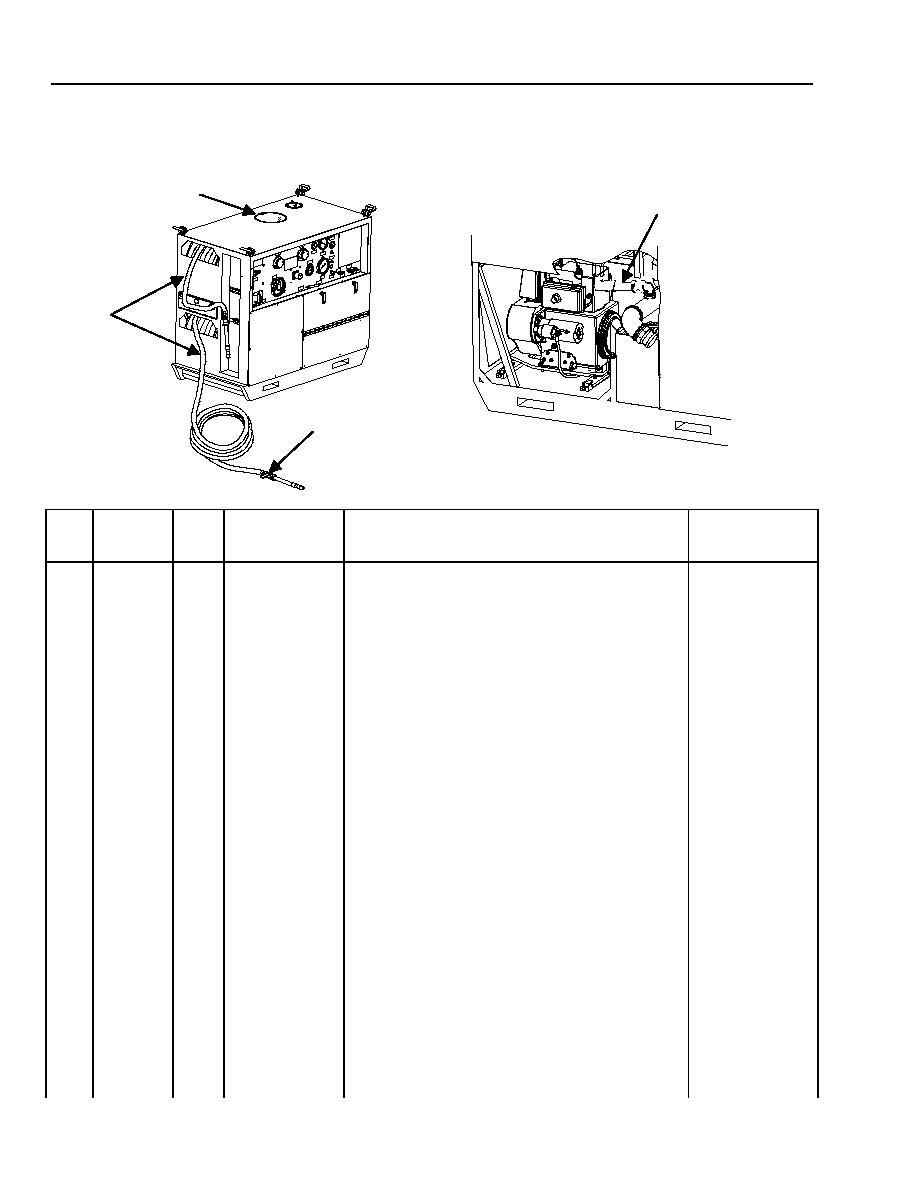

Pump Unit

(Cont)

Both gun

See that a gun assembly is on each of the discharge

Gun Assembly

BEFORE

6

assemblies

hoses. Check that the gun handle operates the valve.

and Slurry

inoperative.

Close the valves. Inspect the gun assembly and slurry

Nozzle

nozzle assembly for dirt and hardened slurry. Inspect

Assembly

the threaded fittings for nicks, burrs, or other damage.

Inspect the gun handle for cracks, chips, twists, bends,

or other damage that would interfere with efficient

operation. Inspect the extension pipe and adapter for

cracks, bends, holes, being out of round, or other

damage that would affect operation of the gun

assembly.

Check that there are no foreign objects or sediment in

Prime-Detergent

BEFORE

7

Foreign objects or

tank. Clean if necessary. Close VALVE NO. 4

Tank Assembly

sediment are in

PRIME on control panel. Fill tank with water and

and Tank Lid

tank. Tank leaks

check for leaks.

continuously.

Inspect discharge hoses for leaks, breaks, or other

Discharge Hose

BEFORE

8

Both discharge

damage.

Assemblies

hoses leak

continuously.

a. Inspect the eductor hose for leaks or breaks.

Eductor Hose

BEFORE

9

Eductor hose

Assembly

leaks.

b. Make sure hose clamps are tight.

0016 00-6