TM 3-4230-237-10

0016 00

OPERATOR'S PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS) - Continued

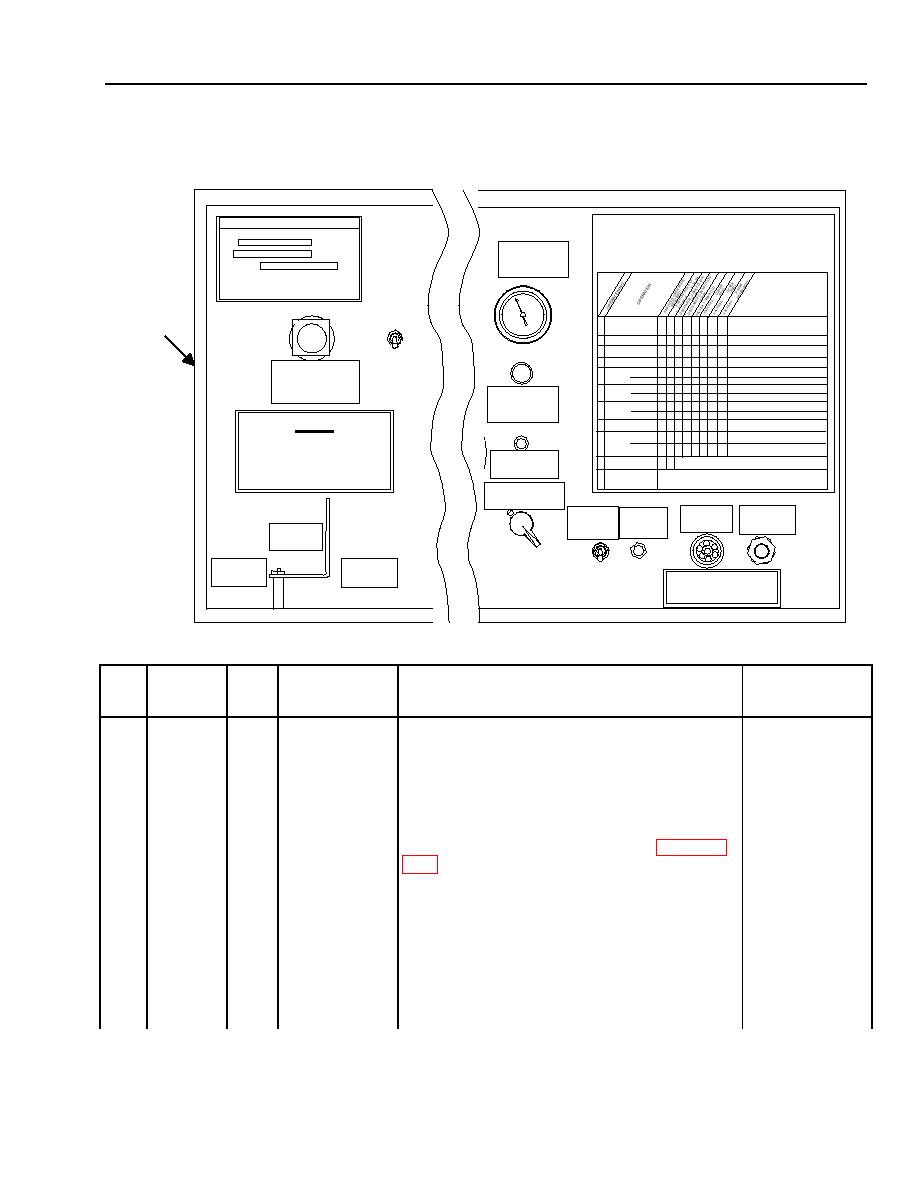

Table 1. Before Operation PMCS for M12A1 DED Decontaminating Apparatus - Continued.

STARTINGPROCEDURE

CAUTON:Donot operate pumpdryorwhen discharge pressureis below 60p.s.i.g.

I

DECONTAMINATING APPARATUS M12A1

READ THEMANUAL

SERNO.

1.Checkallvalve settingsbefore startingandclose all circuit breakers before starting.

2.If temperatureisbelow 40 degrees Fahrenheit,activateenginepre-heater for10seconds.

3.Turn startingswitch to start.

BATTEETER

VOLTM-

NSN

4.Whenenginestarts,releasestart switchtorunposition.

5.Checkallgages to insure properoperation.

VALVEPOSITION

PBAU PGRADE DATE

6.PrimeDetergent Valve#4 must beclosed whenPrime-Detergent tank is empty.

O -OPEN X- CLOSED

REMARKS

U.S.

PRIME DRY PUMP

*

**

*TOTANK AGITATORCONNE T ON E INCH HOSE

C

26

1.

TURN ON FUELSUPPLY

--

S

ON CAP O

X

X

O

**OPENFOR 1MINUTE BE ORE STARTING, THEN

F

START (SEE PROCEDURE)

CLOSE TOHALFWAYFOR REMAINDEROF PRIME

OPERATION(SEE 6 ABOVE)

*

2.

FILL TANK WITHWATER

1

S

ON CAP O

X

X

X

*TOAGITATOR CONNECT ONE INCHHOSE

*

3.

BLEND SLURRY

2

T

ON CAP O

X

X

X

*TOTANK BLENDERADD ANTISET

THENADD STB.

*

4.

AGITATE SLURRY

3

T

ON CAP O

X

X

X

*TOTANK AGITATOR

HEATER OFF

DIS HARGE UPP R REEL 2,3

C

E

T

CAPCAP

O

X

O

X

REATEPTACLE OFF

HE ER

C

5.

SLURRY

LOWER REEL 2,3

T

CA CAP

P

O

O

X

X

RECEPTACLE

AND SWITCH

AN D

S/

ON

D IS HARGE UPPER REEL 1

C

/T

CA CAP

P

O

X

O

X

LOW W IL

LO O

SWITCH ON

6.

S/

WATER

LOWERREEL

1

/T

CAP

CAP O

O

X

X

OIL PRESSURE

S/

*

**

*FROMHEATER

D IS HARGE UPP R REEL

C

E

1

/T

ON

ON

X

X

O

X

**TOHEATER

LIGHT

7.

S/

*

**

*FROMHEATER

H OT W TER LOWER REEL 1

A

/T

ON

ON

X

O

X

X

**TOHEATER

CAUTION

8.

PUMP WATERONLY

S/

*

TOHEATEROR OTHER

1

/T

ON CAP

O

X

X

X

*TOHEATER OR OTHE

R

DISCHARGE FOAM

S/

*

TO AVOID FREEZE DAMAGE KEEP PUMP

UPPER REEL

1

/T

CAP CAP O

X

O

O

*ADJUSTFOR PROPERBLEND

9.

DRAIN VALVE OPEN WHEN EQUIPMENT IS

ORDETERGENT

S/

M AIN

LOWERREEL 1

/T

CA CAP O O

P

X

O

*ADJUST FOR PROPER BLEND

NOT IN OPERATION.

SIYSUIEM

C RC T T

10.

FLUSH SYSTEM

1

S

OPENTANK DRAIN ANDFLUSHTANK THOROUGHLY, THEN OPENPUMP DRAIN

AND FLUSH HOSER E LS AND DISCHARGE CONNECTIONS (SEE MANUAL)

E

B REA K ER

11. SHUTDOWN PROCEDURE

TURN START SWITCH TOOFF POSITION.

CAP ALLPIPES AND CLOSE ALL VALVES EXCEPT PUMP DRA NVALVE.

I

OPEN ALLCIRCUIT BREAKERS

.

IGNITISTOPITCH

ON SW

STOP

RUN

START

ENGINE

PRIR EAT

C -HUIT

EC

RETURN FUEL

FUEL OUT

PRE-HEAT

TO TANK

CIRCUT

I

TO BURNER

SWITCH

BR AKER

E

DRAIN

DRA-

OP- N

CLOSED

CL OS-

OPE

CAUTION: ENSURE PROPER

ENGAGEMENT OF QUICK

DISCONNECT COUPLINGS

Procedure

Not Fully

Item

Interval

Man

Item to be

Mission

No.

Hour

Checked/

Capable If:

Serviced

Pump Unit

(Cont)

a. The control panel can be inspected without having

Control Panel

BEFORE

26

to remove it from the pump unit assembly. Wipe all

Assembly

switches and gages with cloth to remove accumulated

dirt. Clean the control panel with a cloth (Page 0028

parts or damaged leads. Inspect gages for cracked

dials.

b. Inspect that HEATER RECEPTACLE AND

SWITCH is securely fastened to the control panel.

Light does not

c. Turn IGNITION switch to RUN but do not start

illuminate.

engine. LOW OIL PRESSURE LIGHT should

illuminate.

0016 00-15