TM 3-4230-237-10

0016 00

OPERATOR'S PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS) - Continued

Table 1. Before Operation PMCS for M12A1 DED Decontaminating Apparatus - Continued.

28

29

30

27

Procedure

Not Fully

Item

Interval

Man

Item to be

Mission

No.

Hour

Checked/

Capable If:

Serviced

a. Check that tank is fastened to skid base assembly.

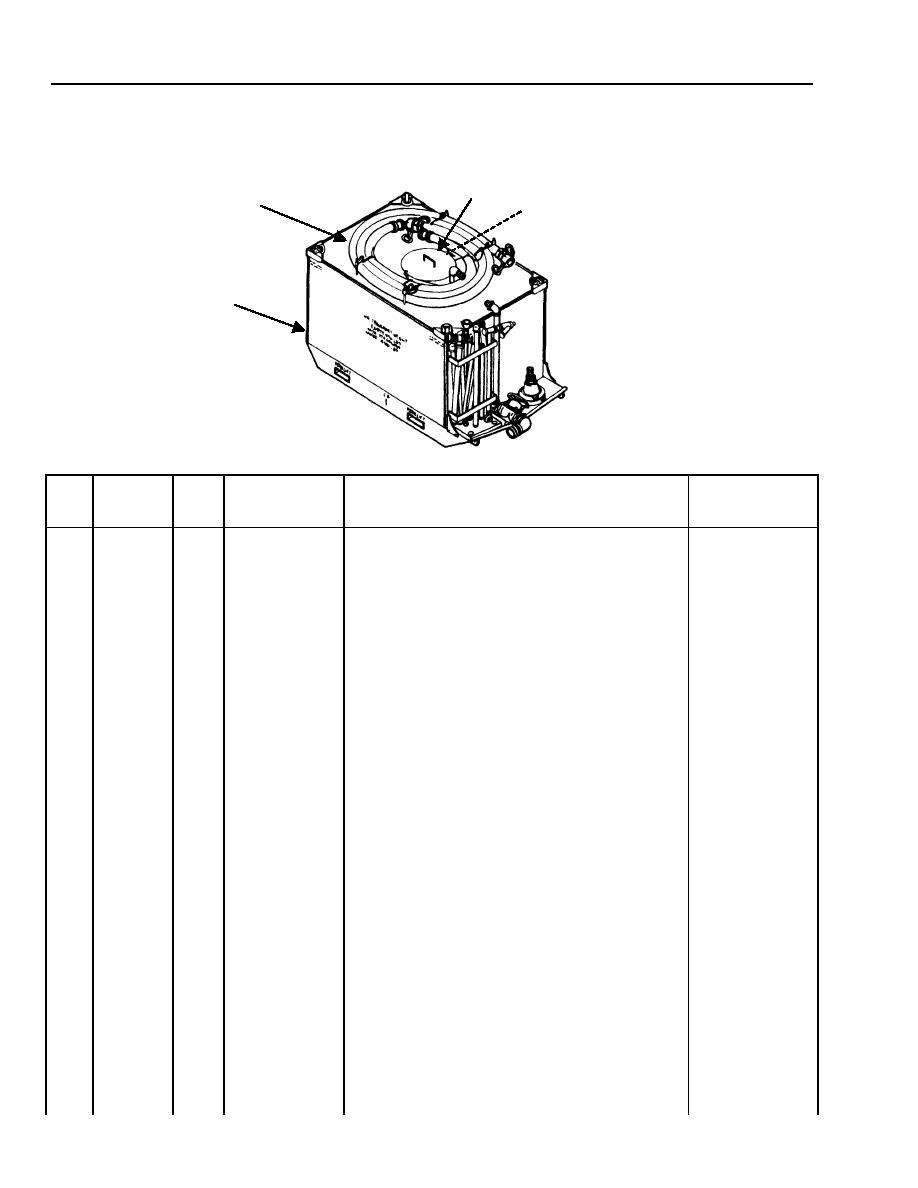

Tank Unit

BEFORE

27

b. Check that suction hose is stowed properly on top

of the tank unit.

Tank leaks

c. Inspect for broken welds, leaks, obstructions, loose

continuously.

pipe fittings, and missing parts.

a. Inspect the hopper assembly for broken welds and

Hopper

BEFORE

28

evidence of leaks.

Assembly

Quick disconnect

b. Check that quick disconnect on blender pipe is not

is out of round or

out of round or loose.

loose.

Screen is

c. Check that dry slurry has not accumulated on

completely

inside screen.

blocked.

d. Check that the blender hose is coiled inside the

hopper when not in use.

Gaskets are

Check that quick release couplings have gaskets

Suction Hose

BEFORE

29

missing. Hose

installed. Check for leaks, breaks, or other damage.

Assembly

leaks

continuously.

Gaskets are

Check that quick release couplings have gaskets

Blender Hose

BEFORE

30

missing. Hose

installed. Check for leaks, breaks, or other damage.

leaks

continuously.

0016 00-16