TM 5-3800-205-10-2

Table 1. Preventive Maintenance Checks and

Services (PMCS) for 613CWD Water Distributor - Continued.

LOCATION

ITEM TO

ITEM

MAN-

NOT FULLY MISSION

CHECK/

NO.

INTERVAL

HOURS

PROCEDURE

CAPABLE IF:

SERVICE

(3) Apply and release service brake

75

Weekly

Brake Air

System EMS

pedal until air pressure drops to

(Con't)

Action

65 psi (448 kPa). EMS brake air

Alarm Test

pressure indicator light and

EMS action light should illumi-

nate. EMS action alarm should

sound.

(4) Notify Unit Maintenance of any

malfunction.

Fully unwind hose from hose reel. Damage that would impair

76

Weekly

Hose Reel

Inspect hose for cuts, cracks, tears or operation is evident, if

and Auxil-

required for mission.

dry rot. Inspect nozzle for damage.

iary Hose

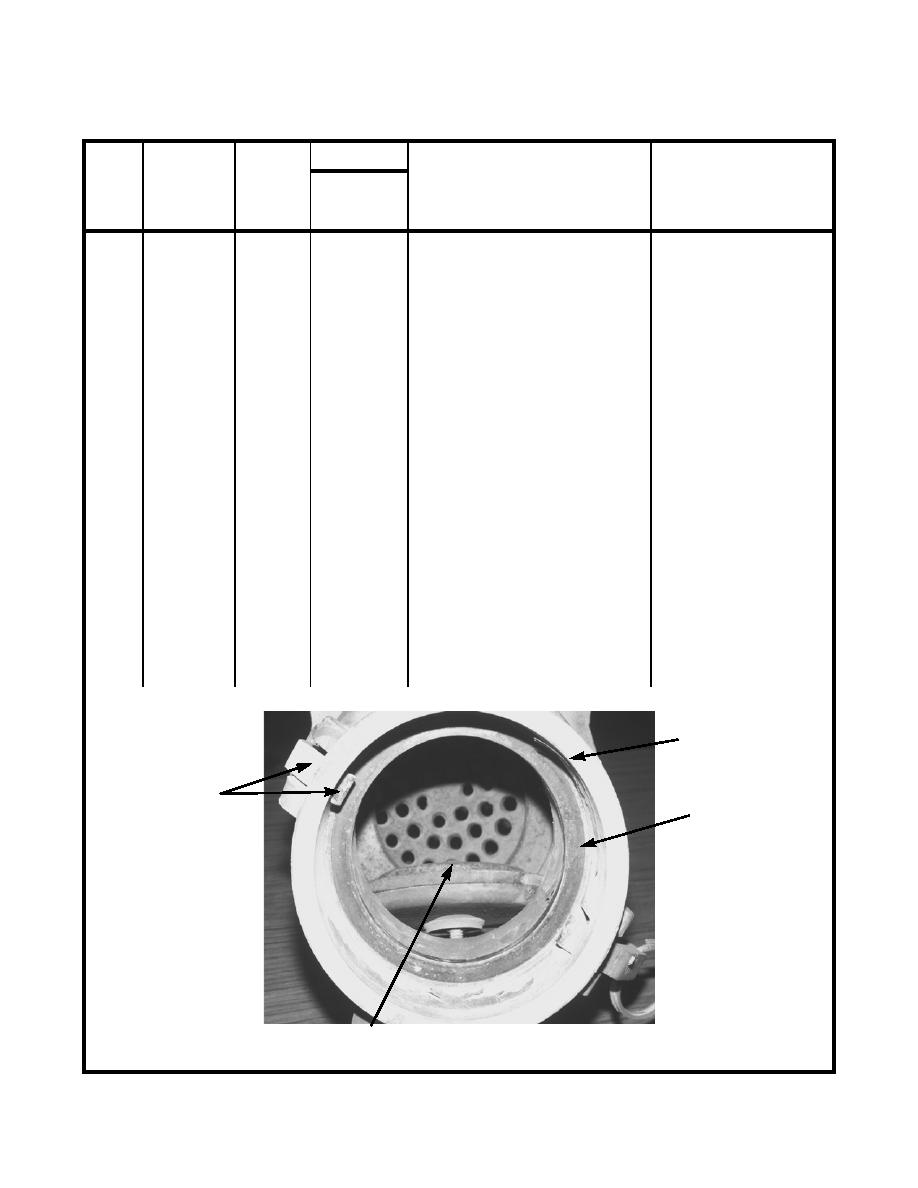

a. Unlock camlocks, turn and remove

77

Weekly

Foot Valve

foot valve from suction loading

and Suction

inlet.

Hoses

b. Check that flapper valve moves b. Flapper valve is frozen, if

freely.

foot valve is required for

mission.

c. Ensure that gasket is present and in c. Gasket is missing or dam-

good condition.

aged, if foot valve is

required for mission.

d. Reinstall foot valve on suction load-

ing inlet and lock camlocks.

FOOT

VALVE

CAMLOCK

GASKET

390-1967

FLAPPER

VALVE

0013 00-57