d. Cleaning, Inspection, and Repair.

(1) Clean all parts with an approved cleaning solvent and dry thoroughly.

(2) Inspect the crankshaft journals for wear and out-of-roundness. The main bearing journals should

be 1.8100 to1.8105 inches.

(3) Inspect the main bearings for wear.

(4) Inspect all hardware for cracks, breaks, or damaged threads. Replace as necessary.

(5) Inspect the crankshaft surfaces for cracks. Inspect carefully at fillets and counter bores, areas

where cracks frequently originate. Repair or replace the crankshaft as necessary. Inspect the

keyways in the crankshaft and test the key for snug fit. Remove any burrs or nicks in the key or

key-way.

(7) Inspect the crankshaft and nut threads. Replace any damaged nuts.

(8) Inspect the crankshaft gear for worn, broken, chipped or damaged teeth. Replace a defective

gear.

(9) Inspect the crankshaft oil seal in the gear housing front section. Replace a worn or damaged seal.

e. Reassembly.

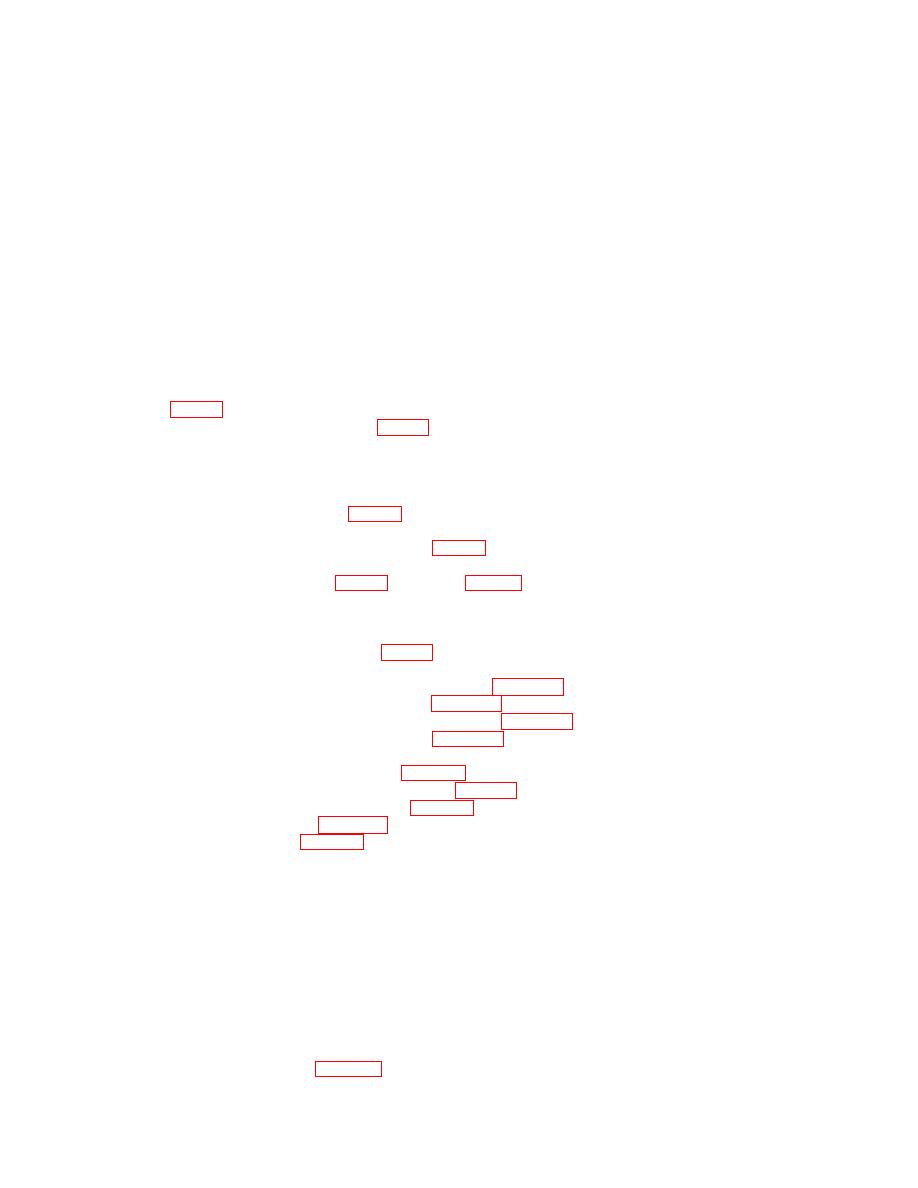

(1) Preheat the bearings (17 and 29, fig.40) in oil at 4000 F., and slide into position in the crankshaft

(1).

(2) Press the bearing cups (18 and 30) in the main bearing plate (26) and bearing retainer plate (13,

(3) Position the woodruff key (15, fig. 40)in the crankshaft (1).

(4) Position the oil slinger (20) on the crankshaft (1).

(5) Preheat the crankshaft gear (19) in oil at 4000 F., and slide into position on the crankshaft (1).

f. Installation.

(1) Position the crankshaft (1, fig. 40) in he crankcase and align the timing marks with the camshaft

gear.

(2) Position the bearing retainer plate(13, fig. 38) on the crankcase and se-cure with the lockwashers

(9) and screws (8).

(3) Position the gasket (22, fig. 40), shims,(23 and 24), gasket (25) and main bearing plate (26) on

the crankcase and secure with the lockwashers (27)and capscrews (28).

(4) Check the main bearing end clearance. The proper clearance is 0.002 to 0.004of an inch. If the

end clearance exceeds0.002 of an inch, add or remove shims until the clearance is correct.

(5) Install the idler gear shaft (11, fig. 38)and idler gear (10) in the crankcase and secure with the

setscrew located on the left-hand side of the crankcase.

(6) Install the piston and connecting rod assembly (para. 134f).

(7) Install the oil pan and pump assembly(para. 132f).

(8) Install the water pump and rear panel assembly (para. 125).

(9) Install the engine and pump assembly(para. 121).

(10) Install the cylinder heads (para.107d).

(11) Install the fuel pump and adapter(para. 82g).

(12) Install the flywheel and flywheel housing (para. 68).

(13) Install the cylinder head shrouding(para. 68).

(14) Install the manifolds (para. 106f).

(15) Install the canopy (para. 68).

137. Engine Cylinder Block and Valve Assemblies

a. Description. The cylinder blocks are cast in pairs and are provided with cooling fins. The blocks are

mounted on the crankcase and house the valves and pistons. The cylinder block can be removed, but not

replaced, without disassembly of piston rods. The adjustable rotary valves are actuated by mushroom tappets

located in the crankcase. The camshaft lobes actuate the tappets. The tappets cannot be removed with out

the camshaft. The firing order of the cylinders is 1, 3, 4, 2. No. 1 cylinder is the nearest to the flywheel in the

left bank of cylinder and No. 3cylinder is behind No. 1. No. 2 is nearest to the flywheel in the right bank and

No. 4 is behind it.

b. Removal.

(1) Remove the canopy (para. 68).

89