TM 55-1930-209-14&P-1

12-9.3 Using air Impact wrench with air stations 1 thru 5 and 7

WARNING

Always wear safety glasses when operating an air impact wrench.

Use only impact wrench sockets. DO NOT use sockets from a hand wrench set.

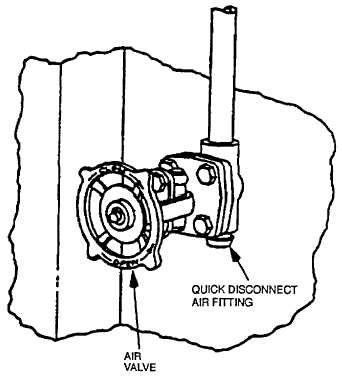

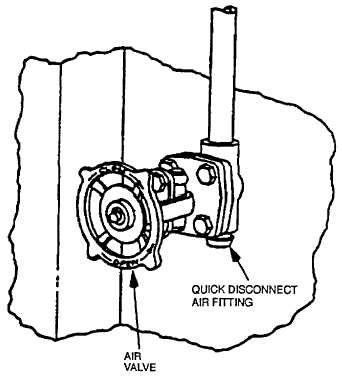

Figure 12-8. Air Station Valve and Quick Disconnect

12-9.3.1 Pre-operational procedures

a.

Make sure compressed air system has been purged of moisture within last 4 hours. If not, open draincock on

bottom of air filter 1 until all moisture has been drained from system.

b.

Select proper sockets for the assigned task. Loose, worn, or cracked sockets reduce wrench impact power and

may create a hazard for the operator. When possible, use deep sockets in place of long, springy extension bars

which absorb impact. Always use simplest socket hookup possible, as multiple connections reduce available

impact.

c.

If more than one air hose is necessary to reach the job location, all except the short leader hose to the tool should

be 1/2 inch inside diameter. If couplers are used, they must not be directly connected to the wrench air inlet. This

makes the tool bulky and unwieldy and puts unnecessary strain on the tool inlet threads.

d.

Once a day, before using the wrench, pour about one tablespoon of oil into air inlet. Use a turbine or spindle

grade oil with a 100-150 Saybalt Universal Seconds viscosity which contains a rust inhibitor. This oil goes in the

air inlet where the hose is connected, not in the oil hole on the side of the wrench body.

e.

Make sure air inlet screen is clean and installed in hose adapter.

12-13