TROUBLE

PROBABLE CAUSE

CHECK AND REMEDY

12

Hoist will not

a)

Open circuit

a) See Item 11a.

operate at fast

b)

Open speed selecting

b) Open or shorted winding in speed select-

speed in either

control circuit

ing contractor coil. Loose connection or

direction

broken wire in circuit. Mechanical bind-

ing in contactor. Control station contacts

not making or opening. Replace coil;

repair connection, contactor or control

station.

c)

Phase failure

c) See Item lb.

13

Hook will not

a)

Excessive load

a) See Item 6b.

raise at slow

b)

Phase failure

b) See Item lb.

speed

c)

Open speed selecting

c) See Item 12b.

control circuit.

d)

Brake not releasing

d) See Item lg.

14

Hook will not

a)

Phase failure

a) See Item lb.

lower at slow

b)

Open speed selecting

b) See Item 12b.

speed

control circuit.

c)

Brake not releasing

c) See Item lg.

15

Hook will not

a)

Excessive load

a) See Item 6b.

raise at fast

b)

Phase failure

b) See Item lb.

speed

c)

Brake not releasing

c) See Item lg.

16

Hook will not

a)

Phase failure

a) See Item 6b.

lower at fast

b)

Brake not releasing

b) See Item lg.

speed.

17

Hook moves in

a)

Phase reversal

a) Wiring reconnected improperly Inter-

proper direction

change two leads of motor winding that is

at one speed -

out of phase at the speed selecting relay.

wrong direction

at other speed.

To Detect Open and Short Circuits In Electrical Components

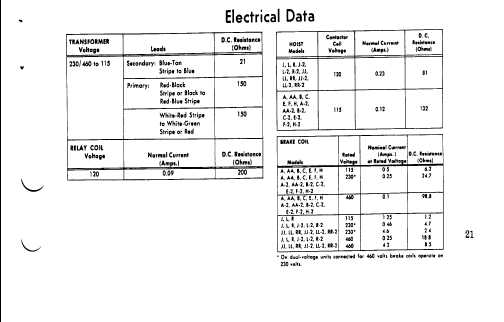

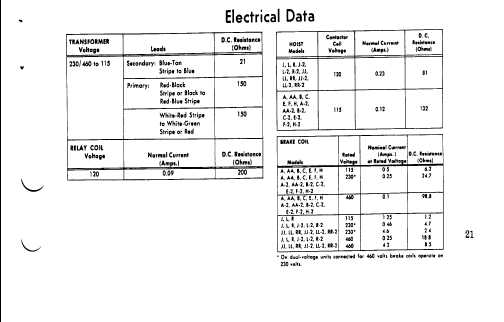

Open circuits in the coils of electrical components may be detected by isolating the coil and checking for

continuity with an ohmmeter or with the unit in series with a light or bell circuit.

Shorted turns are indicated by a current draw substantially above normal (connect ammeter in series with

suspected element and impose normal voltage) or D. C. resistance substantially below normal. The current method is

recommended for coils with very low D. C. resistance.

Motor current draw in the stator should be measured with the rotor in place and running. Brake, relay and

contactor coil current should be measured with the core iron in operating position.

21