9.

Moving one traveling nut toward the other

increases hook travel and away from the other

decreases the travel. Now, turn the nut nearest

the switch indicated as the "LOWER LIMIT

SWITCH" until it just breaks the limit switch

contacts. An audible click will be heard as the

switch opens. Continue to rotate the nut toward

the switch an additional two full teeth on single

limit switch gear reduction or one full tooth on

double limit switch gear reduction, refer to Table

I.

10.

Reposition the guide plate in the next slot and

securely tighten screws.

11.

Reconnect hoist to power supply, and check the

stopping point of hook by first raising the hook

about 10 inches, then lower the hook by jogging

cautiously until the lower limit switch stops the

downward motion. The stopping point of hook

should be the desired lower position. If not,

repeat the above instructions.

12.

Double check setting by raising the hook about

2 feet and then run the hook into the lower limit

with the v (DOWN) control held depressed.

13.

Fine adjustment of the lower limit setting may

be obtained by inverting the guide plate in Step

10. The offset on the plate gives adjustments

equivalent to 1/2 notch, see Table I for the

"Hook Travel Per Notch of Limit Switch Nut".

When inverting the plate, it may be necessary to

use the notch adjacent to the one used in the

preliminary setting.

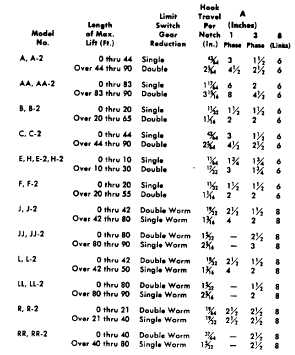

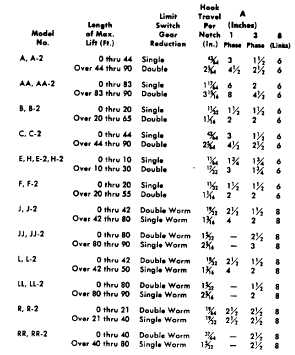

TABLE I

ENCLOSED TYPE LIMIT SWITCHES

Hook Travel Per Notch of Limit Switch Nut

SECTION D - TROUBLE SHOOTING

All Hoists

TROUBLE

PROBABLE CAUSE

CHECK AND REMEDY

1.

Hook does not

a)

No voltage at hoist - main line

a) Close switch, replace fuse or reset breaker.

respond to the

or branch circuit switch open;

control station.

branch line fuse blown or cir-

cuit breaker tripped.

b)

Phase failure (single phasing,

b) Check for electrical continuity and repair

three phase unit only) - open

or replace defective part.

circuit, grounded or faulty con-

nection in one line of supply

system, hoist wiring, reversing

contactor, motor leads or wind-

ings.

c)

Upper or lower limit switch has

c) Press the "other" control and the hook

opened the motor circuit.

should respond. Adjust limit switches as

described on page 16.

d)

Open control circuit--open or

d) Check electrical continuity and repair or

shorted winding in transformer,

replace defective part.

reversing contactor coil or

speed selecting relay coil; loose

connection or broken wire in

circuit; mechanical binding in

contactor or relay; control station

contacts not closing or opening.

18