CAUTION: THE "A" DIMENSIONS SHOWN IN THE

TABLE ARE THE MINIMUM ALLOWED FOR SAFE

OPERATION AND SHOULD NOT BE REDUCED.

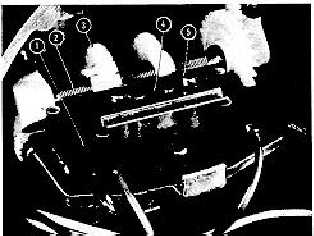

Figure 14.

ENCLOSED TYPE LIMIT SWITCHES, Models A thru H

and A-2 thru H-2.

1. Limit switch sub-assy. 4. Guide plate

2. Limit switch shaft

5. Screws and lock washers

3. Traveling nuts

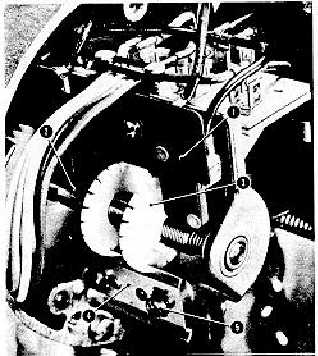

Figure 15.

ENCLOSED TYPE LIMIT SWITCHES, Models J thru

RR and J-2 thru RR-2.

1. Limit switch sub-assy. 4. Guide plate

2. Limit switch shaft

5. Screws and lock washers

3. Traveling nuts

SETTING UPPER LIMIT SWITCH

5.

Refer to Table I The "A" dimensions given are

the minimum distances that should be set

between top of hook block and bottom of hoist.

In other words, the highest allowable hook

position.

6.

Reconnect hoist to power supply.

7.

Run hook to the desired upper position,

cautiously operating the hoist without a load.

8.

Disconnect hoist from power supply.

9.

Moving one traveling nut toward the other

increases hook travel and away from the other

decreases the travel. Now, turn the nut nearest

the switch indicated as the "UPPER LIMIT

SWITCH" until it just breaks the limit switch

contacts. An audible click will be heard as the

switch opens. Continue to rotate the nut toward

the switch an additional two full teeth on single

limit switch gear reduction or one full tooth on

double limit switch gear reduction, refer to Table

I.

10.

Reposition the guide plate in the next slot and

securely tighten screws.

11.

Reconnect hoist to power supply and check the

stopping point of hook by first lowering the hook

about 10 inches, then raise the hook by jogging

cautiously until the upper limit switch stops

upward motion. The stopping point of hook

should be the desired upper position. If not,

repeat the above instructions.

12.

Double check setting by lowering the hook about

2 feet and then run the hook into the upper limit

with i (UP) control held depressed.

13.

Fine adjustment of the upper limit setting may

be obtained by inverting the guide plate in Step

10. The offset on the plate gives adjustments

equivalent to 1/2 notch, see Table I for the

"Hook Travel Per Notch of Limit Switch Nut".

When inverting the plate, it may be necessary to

use the notch adjacent to the one used in the

preliminary setting.

SETTING LOWER LIMIT SWITCH

5.

Refer to Table I The "B" dimensions given are

the minimum number of load chain links that

should be set between the loose end link and

the hoist frame on the loose end side of the

chain. In other words, the lowest allowable hook

position.

CAUTION: THE "B" DIMENSIONS SHOWN IN

THE TABLE ARE THE MINIMUM ALLOWED

FOR SAFE OPERATION AND SHOULD NOT

BE REDUCED.

6.

Reconnect hoist to power supply.

7.

Run the hook to the desired lower position,

cautiously operating the hoist without a load.

8.

Disconnect hoist from power supply.

17