CHAPTER VI - MISCELLANEOUS COOLERS

SECTION I COMPARTMENT WATER COOLERS

1 - Explanation of the Bottle -

Comportment Refrigeration System

2 - Explanation of the Pressure-

Comportment Refrigeration System

3 - Maintenance

4 - Service and Trouble Shooting

SECTION II

EXPLOSION PROOF WATER COOLERS

SECTION III

BELT DRIVEN OR OPEN TYPE

REFRIGERATION SYSTEM WATER

COOLERS

1 - Explanation

2 - Maintenance

SECTION I - COMPARTMENT WATER COOLERS

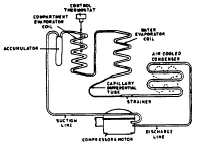

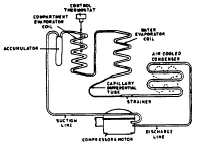

SCHEMATIC -REFRIGERATION

COMPARTMENT-BOTTLE WATER COOLER

1.

EXPLANATION OF THE BOTTLE -

COMPARTMENT REFRIGERATION SYSTEM

The high pressure liquid refrigerant passes through the

capillary tube to the water evaporator. Upon leaving the

water evaporator, it travels through a weight check

valve, which prevents freezing of the water system, to

the compartment evaporator. After circulating through

the compartment coil, the refrigerant then passes

through the accumulator and back to the compressor.

The system is controlled by one thermostat whose

power element is strategically located on the side of the

compartment evaporator. When the water demands

more cooling, the warmer refrigerant vapor passes from

the water evaporator through the weight check valve to

the compartment evaporator. This in turn warms the

power

element

of

the

thermostat

causing

the

compressor to start, regardless of the temperature of the

compartment. The compressor will also start when the

compartment

requests

cooling

and

the

water

temperature is correct.

2.

EXPLANATION OF THE PRESSURE -

COMPARTMENT REFRIGERATION SYSTEM

Early designs of the compartment, pressure water

system use a solenoid valve in the water evaporator

outlet controlled by a thermostat to prevent freezing of

the water cooling system. A capillary tube branching

from a specific turn of the water evaporator supplies

refrigerant for cooling of the compartment evaporator.

When the water requires more cooling, the thermostat

contacts close causing

the solenoid valve to open and the compressor to start.

When the compartment only requires more cooling, its

thermostat contacts close causing the compressor to

start.

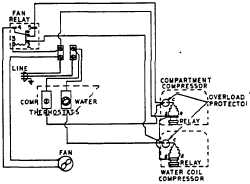

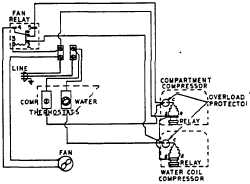

Later models use two refrigeration systems,

each operating independently of one another. Each

system has its own controlling thermostat to operate and

control its system.

Both refrigeration systems share a common air

cooled double circuited condenser and use one fan.

A relay is employed to actuate the fan when

either system starts.

WIRING DIAGRAM FOR COMPARTMENT

PRESSURE WATER COOLER

3.

MAINTENANCE

An occasional defrosting of the compartment evaporator

is the only difference for general maintenance of the

cooler. When defrosting of the compartment is required,

disconnect electrical power supply. Remove ice cube

trays and place a pan of hot water in the compartment.

The door can remain open. Defrosting requires about 15

minutes depending upon the frost build-up. When

completed, fill the ice trays with fresh water and connect

the electrical supply.

4.

SERVICING AND TROUBLE SHOOTING

When trouble is encountered with the compartment

water coolers, service procedures mentioned earlier in

this manual should be followed.

15