CHAPTER VI

SEC. II · SEC. III

SECTION II - EXPLOSION PROOF COOLERS

Explosion proof water coolers are designed to

operate

in

potentially

combustible

atmospheres

containing inflammable or explosive mixtures of vapors,

gases or dust. They meet all requirements as defined in

the

National

Electrical

Code

and

Underwriter's

Laboratories for Class I, Groups C and D; Class II,

Groups F and G. Therefore, it is necessary to remove

the cooler from these conditions to a safe working area

before servicing the

refrigeration system or electrical components.

The electrical wiring is run through conduit and

the combination relay-overload and thermostat are

housed in a sealed junction box. To gain access for

servicing, a threaded dome cover is provided.

The refrigeration system is of the hermetic type.

Service procedures mentioned in previous chapters

apply to this cooler.

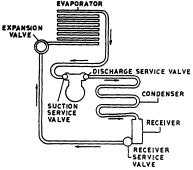

SECTION III - BELT DRIVEN OR OPEN TYPE REFRIGERATION SYSTEM

WATER COOLER

SCHEMATIC-OPEN TYPE

REFRIGERATION SYSTEM

1.

EXPLANATION

Open or belt driven type refrigeration water coolers are

used in areas of odd voltages, D. C. current or other

special applications. They are designed for field

servicing and all parts of the system are replaceable.

The function of the refrigeration cycle is basically

the same as explained in Chapter I, Section II. A

thermostatic expansion valve, instead of a capillary tube,

is used for metering of the refrigerant to the evaporator.

The major difference between the hermetic and

open type refrigeration system is in the compressor and

motor assembly. The open system is supplied with a

crankshaft-cylinder type compressor, which is driven by

an independent motor and V belt. A fan blade mounted

on the motor pulley provides cooling air for the

condenser.

Service shut-off valves are provided on the

suction and discharge sides of the compressor and at

the outlet of the receiver. These valves allow the service

man to work on the system without the loss of a large

amount of refrigerant.

2.

MAINTENANCE

Maintenance of the water cooler with an open type

refrigeration system should be performed periodically by

a competent refrigeration service man. It is vitally

important for proper operation and long life of the cooler.

The service man when performing these services

should:

1 - Oil Motor

2 - Clean Condenser and check for proper air

circulation.

3 - Adjust the V belt tension

4 - Check for refrigerant leaks

5 - Correct refrigerant charge and pressures

6 - Check drinking water temperature and ad-

just thermostat

CAUTION

When thermostat needs replacing,

exact factory replacement should be

used. Others may give faulty service.

IMPORTANT - Never return a cooler with an open type

refrigeration system to the factory for repairs without

specific authorization. The design and assembly of this

type cooler is such that all parts can be quickly changed

in the field and frequently at less cost than packing,

handling and freight in shipment to and from the repair

station.

LITHO IN U.S.A.

16